The Evolution and Future of Cnc Turning Machine Technologies

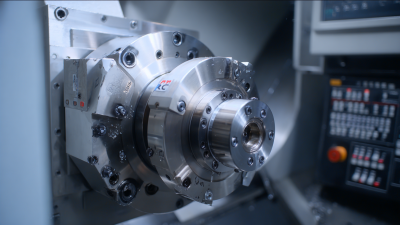

In the rapidly evolving world of manufacturing, the CNC turning machine has emerged as a crucial technology that drives precision and efficiency. According to a recent report from MarketsandMarkets, the CNC machine market is projected to reach USD 100 billion by 2025, with turning machines being a significant segment due to their versatile applications across various industries, including aerospace, automotive, and medical devices. The rise of automation, coupled with advancements in computer numerical control technology, has transformed conventional turning processes, facilitating higher production rates and improved accuracy. As industries increasingly adopt smart manufacturing practices, it is essential to explore the evolution of CNC turning machines and their future trajectory, highlighting how emerging technologies such as IoT and AI are poised to redefine operational capabilities and boost competitiveness in the global market.

The Historical Development of CNC Turning Machines: Key Milestones and Innovations

The historical development of CNC turning machines is marked by a series of key milestones that have significantly transformed the precision machining industry. The journey began in the 1950s when the first numerical control (NC) machines were introduced, utilizing punched tape for programming. This technological breakthrough allowed for automated control of machine tools, which dramatically improved the consistency and accuracy of machining processes.

As the decades progressed, the introduction of computer numerical control (CNC) in the 1970s accelerated the evolution of turning machines. The transition from analog to digital control systems enhanced programmability, enabling more complex designs and operations. Significant innovations during this era included the advent of CAD/CAM software, which streamlined the design and manufacturing process. Furthermore, advancements in servo motors and precision tooling contributed to the growing capabilities of CNC turning machines, making them indispensable in modern manufacturing.

Into the 21st century, the development of smart technologies and automation has further revolutionized CNC turning machines. Today, features such as real-time monitoring, predictive maintenance, and integration with IoT devices are becoming standard. These innovations not only enhance operational efficiency but also pave the way for more sustainable manufacturing practices, ensuring that CNC turning technology remains at the forefront of industrial evolution.

Technological Advancements in CNC Turning: From Conventional to Smart Machines

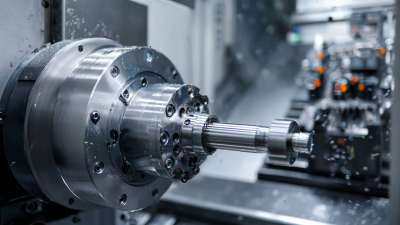

The technological landscape of CNC turning machines is undergoing a significant transformation, marked by advancements that are reshaping precision manufacturing. From conventional machines to smart systems, the evolution has been driven by a need for efficiency, accuracy, and adaptability in manufacturing processes. Recent innovations in CNC drive system technology, such as those developed in South Korea, exemplify this shift, showcasing how localized advancements can enhance performance in machine tools. These developments are not just incremental; they signal a move towards integrated manufacturing systems that leverage smart technology for improved productivity.

Moreover, the integration of Industry 4.0 principles into CNC turning processes is propelling the industry into a new era of connectivity and automation. By utilizing real-time data for monitoring and predictive maintenance, manufacturers can significantly reduce downtime and optimize operational efficiency. The focus on versatility is evident as CNC turning machines adopt multitasking capabilities, enabling them to perform various functions within one setup. This evolutionary journey towards smarter machines epitomizes a broader trend within the manufacturing sector, where technological advancements are fostering a more sustainable and efficient production environment.

Current Market Trends: The Growing Demand for CNC Turning in Various Industries

As industries continue to evolve, the demand for CNC turning machines is surging across various sectors. The machine tools market, which includes CNC technologies, surpassed USD 97.1 billion in 2024 and is projected to grow at a robust CAGR of 7.5% through 2034. This growth is driven by the increasing need for precision components and automation, particularly in industries such as automotive, aerospace, and medical devices. Manufacturers are increasingly relying on CNC turning machines to meet the demands for high-quality parts that require intricate designs and tight tolerances.

Moreover, advancements in technology are transforming the CNC machinery landscape. The incorporation of artificial intelligence and self-optimizing capabilities is enhancing the efficiency and effectiveness of CNC machines, including 5-axis machining centers. These innovations not only streamline production processes but also contribute to significant cost savings over time. As industries recognize the value of precision and automation in achieving operational excellence, the CNC turning market is poised for substantial growth, promising exciting opportunities for manufacturers and users alike.

The Evolution and Future of CNC Turning Machine Technologies

Predictive Maintenance and IoT: Transforming CNC Turning Machine Operations

The integration of predictive maintenance and IoT technologies is revolutionizing CNC turning machine operations, propelling the manufacturing industry towards unprecedented efficiency and flexibility. The shift towards Industry 4.0 underscores the importance of data-driven strategies, with IoT playing a crucial role in enabling real-time monitoring and analysis of machine performance. As highlighted in recent reports, the demand for predictive maintenance solutions is on the rise, driven by the need to minimize downtime and optimize production processes. Companies are now leveraging advanced technologies such as artificial neural networks to enhance predictive capabilities, thus laying the groundwork for proactive maintenance strategies.

A notable trend in the CNC machine sector is the increasing adoption of automation and digitalization. In Europe alone, the CNC machine market is projected to grow significantly by 2033, reflecting broader industry advancements. For instance, the implementation of IoT-based systems allows manufacturers to gain comprehensive visibility into their operations, ranging from individual machines to entire production lines. This level of connectivity not only facilitates predictive maintenance but also supports manufacturers in identifying potential issues before they escalate, ensuring smoother production workflows and ultimately enhancing overall productivity.

Future Outlook: Innovations and Challenges in CNC Turning Technology Advancements

The CNC turning machine industry is witnessing unprecedented innovations driven by advancements in technology and the increasing demand for precision manufacturing. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2026, growing at a CAGR of 6.9% from 2021. This growth is largely fueled by the integration of IoT (Internet of Things) and AI (Artificial Intelligence) into CNC systems, enhancing their capabilities in real-time data analytics and predictive maintenance. Such technologies enable manufacturers to optimize production workflows and significantly reduce downtime.

However, as these advancements unfold, the industry also faces several challenges. The rapid pace of technological change requires continuous investment in operator training and system upgrades. A survey conducted by Deloitte indicates that nearly 70% of manufacturers are concerned about the skills gap in their workforce as new technologies emerge. Additionally, cybersecurity risks pose a substantial threat, as increasing connectivity makes CNC systems vulnerable to cyberattacks. Addressing these challenges will be crucial for manufacturers striving to leverage new technologies while safeguarding their operations and maintaining a competitive edge in the evolving market landscape.

The Evolution and Future of CNC Turning Machine Technologies - Future Outlook: Innovations and Challenges in CNC Turning Technology Advancements

| Dimension | Current Trends | Future Innovations | Challenges Ahead |

|---|---|---|---|

| Automation | Increased use of robotic automation in CNC machining | Integration of AI for predictive maintenance | High initial investment and workforce training |

| Materials | Shift towards lightweight and high-strength materials | Development of advanced alloys and composites | Material processing limitations |

| Precision | Emerging technologies enhancing precision | Nano-precision machining techniques | Maintaining quality control standards |

| Software | Adoption of advanced CAD/CAM software | AI-driven software for optimized machining | Integration challenges with existing systems |

| Sustainability | Focus on reducing waste and energy consumption | Utilization of eco-friendly manufacturing processes | Balancing productivity with environmental goals |

Related Posts

-

Setting New Industry Standards with the Best Cnc Turning Machine

-

Understanding the Advantages of CNC Milling and Turning Applications for Diverse Industries

-

The Evolution of Cnc Machining Parts in Global Manufacturing

-

Top 10 Turning Machining Manufacturers from China at the 137th Canton Fair

-

How to Select the Best CNC Parts for Your Global Supply Chain Needs

-

Exploring the 2025 Tech Revolution: Advantages of the Best CNC Turning Solutions

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219