Unlocking Precision Machining Myths 7 Essential Facts You Should Know

In the realm of modern manufacturing, Precision Machining stands as a pivotal technology driving innovation and efficiency across various industries. According to a report by the National Institute of Standards and Technology (NIST), precision machining contributes approximately $100 billion to the U.S. economy annually, highlighting its significance in the production of high-quality components. Despite its importance, several myths surrounding precision machining persist, often leading to misconceptions about its capabilities and limitations. For instance, many assume that precision machining is only applicable in large-scale operations; however, recent data from the Association for Manufacturing Technology (AMT) indicates that small and medium-sized enterprises (SMEs) are increasingly adopting precision machining techniques, thereby enhancing their competitiveness. By unlocking these myths and understanding the essential facts about precision machining, organizations can harness its full potential, ensuring they remain at the forefront of their respective markets.

Myth-Busting Precision Machining: Understanding the True Costs of Production

When it comes to precision machining, many myths cloud the true costs of production. One prevalent misconception is that higher precision always translates to increased costs. In reality, advancements in technology and better techniques can lead to significant savings. Understanding this aspect can profoundly affect budgeting and resource allocation for manufacturing projects.

**Tip:** Invest in high-quality tools and equipment. Though the initial outlay may be substantial, their durability and efficiency can greatly reduce operational costs over time.

Another common myth is that smaller batch sizes are inherently more expensive. While it’s true that setup costs can impact unit price, modern machining technologies allow for effective small-batch production, leading to competitive pricing. Organizations can leverage this flexibility to diversify their offerings without incurring prohibitive expenses.

**Tip:** Consider additive manufacturing for prototypes or low-volume parts. This approach can drastically cut lead times and costs compared to traditional machining methods while still achieving desired precision.

Unlocking Precision Machining Myths: 7 Essential Facts You Should Know

| Myth | Fact | Impact on Costs | Benefits |

|---|---|---|---|

| Precision Machining is Always Expensive | Cost varies based on technology and materials used | Understanding cost drivers can lead to savings | Optimized production can reduce overall expenses |

| Only Large Companies Can Afford Precision Machining | Small and medium enterprises can also leverage this technology | Access to advanced technologies is expanding | Enhances competitiveness for smaller businesses |

| Precision Machining is Only for Metal | It is also used for plastics and composites | Broadens application scope | Flexibility in material selection enhances innovation |

| Precision Machining Takes Too Long | Modern machines boast rapid production times | Efficiency improvements can lower lead times | Accelerated time to market for products |

| Outsourcing Machining is Always Cheaper | Local production can reduce logistics and communication costs | Hidden costs may outweigh the savings | Support local economies and improve response times |

| Precision Machining is Inflexible | Machining processes can be adjusted quickly | Versatility in production setup | Respond more effectively to market needs |

| High Precision Always Means Low Tolerance | High precision can achieve varying tolerances | Impact on quality and reliability | Enhances product performance through optimal tolerance |

Common Misconceptions: The Reality of Tolerance Standards in Precision Machining

In the realm of precision machining, many misconceptions surround tolerance standards. A prevalent myth is that tighter tolerances always equate to higher quality. However, the reality is that the required tolerance should be dictated by the function of the part rather than an arbitrary figure. According to a report by the Precision Manufacturing Association, approximately 30% of components produced with unnecessarily tight tolerances incur higher costs without any corresponding performance benefit. Understanding the specific requirements for each project can lead to more efficient manufacturing while maintaining quality.

**Tips:** When defining tolerances, always consider the material properties and the intended application. This ensures that the chosen tolerances serve a clear purpose, ultimately optimizing both time and resources during production.

Another misconception is that all precision machining processes can achieve the same tolerance levels. In reality, various methods—such as CNC milling, turning, or grinding—have distinct capabilities regarding tolerance attainment. The American Society of Mechanical Engineers (ASME) outlines that CNC mills can typically achieve tolerances of ±0.005 inches, making them suitable for most applications. Yet, for ultra-precise needs, methods like grinding may be essential to achieve tolerances of ±0.0001 inches.

**Tips:** Research the inherent capabilities of different machining processes before selection. This will help you choose the most suitable method based on your specific tolerance requirements, ultimately improving both efficiency and accuracy.

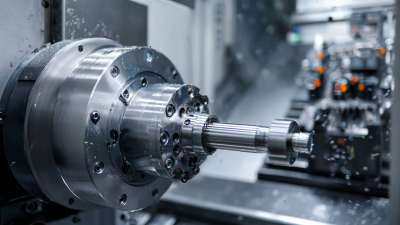

The Role of Advanced Technology: Debunking the ‘Traditional vs. Modern’ Debate

The debate between traditional and modern machining techniques is increasingly relevant as the industry evolves. Advanced technology such as CNC (Computer Numerical Control) machines and additive manufacturing is reshaping the landscape of precision machining. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, highlighting the rapid adoption of automation in manufacturing processes. This shift not only enhances precision but also significantly reduces production time, allowing businesses to stay competitive in an ever-demanding market.

Moreover, advanced technologies facilitate data integration through the Internet of Things (IoT), leading to better machine monitoring and maintenance. A survey by the International Federation of Robotics reveals that robotics installations in machining processes have increased by 30% year-over-year. Such innovations encourage a more strategic approach to manufacturing, moving beyond conventional methods that are often criticized for their limitations in scalability and adaptability. By embracing modern technologies, manufacturers can dispel myths surrounding traditional practices, proving that cutting-edge advancements are essential for achieving operational excellence in today’s fast-paced machining environment.

Workforce Skills Gap: Addressing the Myths Around Labor in Precision Machining

The precision machining industry is often surrounded by misconceptions regarding the skills gap in the workforce.

One prevalent myth is that the labor pool lacks qualified candidates, while in reality, many individuals are eager to enter this field but lack proper training or awareness of career opportunities.

Efforts to enhance educational programs and apprenticeship initiatives are crucial in bridging this gap, enabling a new generation of skilled workers to thrive in precision machining roles.

Another myth suggests that precision machining is only for highly advanced technicians, discouraging potential applicants from pursuing careers in this area.

In truth, the industry accommodates a wide range of skills and educational backgrounds.

By actively promoting awareness of the diverse roles available—from machine operators to engineers—companies can attract a more varied talent pool.

Addressing these misconceptions is vital not only for filling current job vacancies but also for sustaining the industry's growth in the long term.

Sustainability in Machining: Fact vs. Fiction on Environmental Impact and Efficiency

Sustainability in machining is an increasingly relevant topic in the context of modern manufacturing. The intersection of Artificial Intelligence (AI) and Machine Learning (ML) is playing a pivotal role in enhancing production efficiency while minimizing environmental impact. Recent research highlights how these technologies can optimize various machining processes, such as improving cooling tower efficiency and integrating smart industry solutions to reduce waste. By utilizing machine learning algorithms, manufacturers can achieve greater energy efficiency, thus aligning with sustainability goals like those outlined in the United Nations Sustainable Development Goals.

Furthermore, the implementation of eco-friendly machining practices and the adoption of alternative lubricants and cooling methods are becoming essential for reducing the carbon footprint of production processes. Studies have shown that new sustainable performance models are critical for evaluating machining practices and their environmental implications. The application of multi-objective optimization frameworks also signifies a strategic approach to balancing economic, environmental, and practical factors in machining operations. This focus on sustainable development not only addresses immediate production needs but also contributes to long-term environmental stewardship in the manufacturing sector.

Unlocking Precision Machining Myths: Environmental Impact and Efficiency

This chart compares the perceived environmental impact and efficiency of precision machining practices versus their actual data based on recent studies. The focus is on recycling, energy consumption, waste generation, and the use of sustainable materials.

Related Posts

-

Global Trust in Quality Chinese Manufacturing for Best Multi Axis Machining Solutions

-

Unlocking Precision in Cnc Cutting with Advanced Technical Specifications for Global Buyers

-

How to Identify Top Tier Precision CNC Machining Suppliers for Your Manufacturing Needs

-

China Manufacturing Thrives Amidst US China Tariff Challenges with Best Cnc Milling Solutions

-

Revolutionizing Global Manufacturing Standards with Best Cnc Cutting from China

-

Exploring the 2025 Tech Revolution: Advantages of the Best CNC Turning Solutions

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219