Ultimate Guide to Maximizing Efficiency with Axis CNC Machines in Your Workshop

In today's fast-paced manufacturing environment, maximizing efficiency is crucial for workshops striving for competitiveness and productivity. The integration of advanced technology such as Axis CNC Machines has emerged as a game changer in the industry. According to a recent report from the International Federation of Robotics, the adoption of CNC technology can increase machine productivity by up to 30%, significantly reducing cycle times and operational costs. Moreover, the precision and automation provided by Axis CNC Machines enable manufacturers to achieve higher quality outputs while minimizing waste. As businesses look to optimize their processes and scale operations, understanding the best practices for utilizing these machines becomes imperative. This guide will explore essential strategies and insights to harness the full potential of Axis CNC Machines in your workshop, driving both efficiency and profitability.

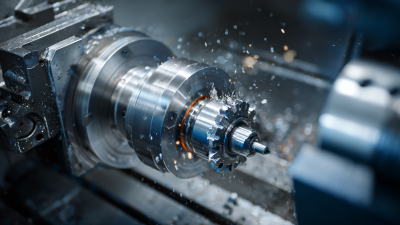

Understanding the Basics of Axis CNC Machines for Workshop Efficiency

Understanding the basics of Axis CNC machines is essential for any workshop aiming to enhance efficiency and productivity. These machines, which utilize computer numerical control to automate machining processes, can dramatically streamline operations by reducing manual labor and minimizing errors. A fundamental aspect of Axis CNC machines is their ability to operate on multiple axes, typically three to five, allowing for complex shapes and designs to be created with precision. By grasping how these axes function—X for horizontal movement, Y for vertical movement, and Z for depth—operators can better plan their machining tasks and optimize the workspace.

Moreover, integrating Axis CNC machines into a workshop can significantly improve both speed and accuracy. With the ability to program intricate designs directly into the machine, production times are drastically reduced, allowing for quicker turnaround on projects. Understanding the various functions and settings of these machines can also help in troubleshooting common issues and performing maintenance, ensuring maximum uptime. Workshops that take the time to familiarize themselves with Axis CNC technology will not only boost their output but also maintain a competitive edge in the increasingly demanding manufacturing environment.

Key Features of Axis CNC Machines That Boost Productivity

Axis CNC machines are revolutionizing modern workshops by enhancing productivity through a variety of key features. One significant aspect is their precision and repeatability. According to a report by the International Federation of Robotics (IFR), CNC machines can improve manufacturing accuracy to within 0.01 mm, which is essential for complex applications in industries such as aerospace and automotive. This level of precision not only reduces material waste but also minimizes the need for extensive post-processing, ultimately saving time and resources.

Another critical feature that boosts productivity is the automation capabilities of Axis CNC machines. Research from MarketWatch suggests that automation in manufacturing can increase productivity by up to 30%. The ability to run unattended shifts allows operators to focus on other tasks, thus maximizing workshop efficiency. Additionally, with advanced software integration, operators can program multiple jobs in advance, leading to a seamless workflow that further enhances output. These innovations position Axis CNC machines as indispensable tools for modern workshops aiming to stay competitive in a rapidly evolving market.

Essential Maintenance Tips for Optimal Performance of CNC Machines

Maintaining CNC machines is critical for ensuring optimal performance and longevity in any workshop. Regular maintenance not only minimizes downtime but also enhances precision and efficiency in operations. Implementing a structured maintenance regimen can significantly reduce the risk of unexpected breakdowns. Key practices include routine inspections, lubrication of moving parts, and calibration checks. These simple tasks can help identify wear and tear before they lead to costly repairs, ensuring that your CNC machines operate at peak performance.

Additionally, embracing modern technologies such as predictive maintenance can revolutionize the way workshops manage their CNC equipment. By utilizing concepts like digital twins, operators can simulate machine conditions and anticipate maintenance needs based on data analytics. This proactive approach leverages the latest advancements in Industry 4.0, allowing for smarter decision-making and resource allocation. Integrating these technologies not only streamlines maintenance but also contributes to the overall growth of the CNC machine market, which is poised for significant expansion in the coming years.

Adopting these essential maintenance tips will ultimately lead to sustained efficiency and profitability in your CNC operations.

Strategies for Integrating CNC Technology into Your Existing Workflow

Integrating CNC technology into your existing workflow is crucial for maximizing efficiency and productivity in your workshop. One effective strategy involves managing machine setup and production runtime effectively. By simplifying the setup processes and minimizing downtime between jobs, workshops can significantly improve the throughput of their CNC machines. Consider developing standardized setup procedures or investing in quick-change tooling to streamline transitions between projects.

Additionally, implementing a flexible assembly system ensures that your production line can adapt to changing demands and workloads. Just as seen in automotive manufacturing, where flexible systems are put in place to accommodate various vehicle models, a similar approach can enhance CNC operations. This adaptability fosters a responsive workflow that can better meet customer needs while reducing waste and improving overall production efficiency. By focusing on these areas, workshops can effectively leverage CNC technology to create a more productive and cost-effective manufacturing environment.

Choosing the Right Software to Maximize Your CNC Machine's Potential

When it comes to maximizing the potential of Axis CNC machines in your workshop, selecting the right software is crucial. The landscape of CAM software offers a variety of options, especially free software, which can serve as an excellent entry point for both hobbyists and professionals looking to refine their skills. This accessibility encourages experimentation and learning, paving the way for more complex applications in the future. By starting with free tools, users can gain valuable insights and hands-on experience managing CNC operations without significant initial investment.

Moreover, addressing manufacturing software challenges can significantly boost efficiency. The right software not only streamlines operations but also resolves common issues that teams face, such as integration with existing workflows and adapting to new machining techniques. A well-chosen software suite empowers users to unlock their CNC machine's full potential, resulting in enhanced productivity and superior output quality. This informed decision-making in software selection is vital to harnessing the capabilities of your Axis CNC machines effectively, ultimately transforming your workshop into a hub of innovation and efficiency.

Related Posts

-

Revolutionizing Global Supply Chains with Advanced CNC Parts Machining Technologies

-

7 Insider Secrets for Sourcing High Quality Cnc Turning Parts Globally

-

5 Essential Tips to Optimize Your CNC Turning and Milling Processes for Better Efficiency

-

Choosing the Right Manufacturer for Best Cnc Parts and Tailored Solutions for Your Needs

-

Understanding Industry Production Standards for the Best Multi Axis Cnc Milling Machine

-

Explore the Rise of Axis Cnc Machines at the Record Breaking Canton Fair 2025

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219