The Ultimate Guide to Mastering Cnc Cutting Techniques for Your Business Success

In today's highly competitive manufacturing landscape, mastering CNC cutting techniques has become essential for businesses aiming to enhance operational efficiency and product quality. According to a report by Technavio, the global CNC machine market is expected to grow by over 5% annually, driven by increasing automation and demand for precision machining. Effective CNC cutting not only reduces material wastage but also accelerates production times, which is critical as industries face rising pressure for swift turnarounds and lower costs. Furthermore, implementing advanced CNC cutting strategies can lead to substantial cost savings, with some estimates suggesting up to a 30% reduction in operational expenses. As such, understanding the various challenges associated with CNC cutting—such as the complexities of different materials, tool wear, and programming inaccuracies—can be the difference between business success and stagnation. This guide will delve into common problems associated with CNC cutting and offer practical solutions to help you navigate this intricate field.

Understanding CNC Cutting: A Comprehensive Overview of Techniques

CNC (Computer Numerical Control) cutting has become a cornerstone of modern manufacturing, offering precision and efficiency that manual methods cannot match. Understanding the various CNC cutting techniques is essential for any business looking to enhance productivity and maintain a competitive edge. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $117.34 billion by 2026, growing at a CAGR of 6.2%. This growth underlines the importance of mastering CNC techniques to optimize output while reducing waste and costs.

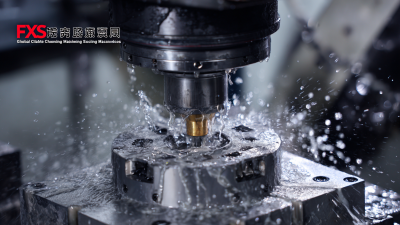

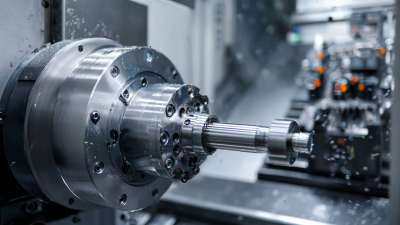

One key technique is CNC milling, which allows for complex shapes and high levels of detail. It can be applied across diverse materials such as metals, plastics, and wood, making it versatile for different industries. Another important method is CNC plasma cutting, which is ideal for cutting thick materials and is lauded for its speed and efficiency. Companies that adopt these techniques often see reductions in production time by up to 50%.

**Tip:** Regular maintenance of CNC machines can significantly enhance their lifespan and performance, ensuring accurate cuts and minimizing downtime.

Moreover, utilizing software that integrates CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) can streamline the transition from design to production. By investing in training for your team to become proficient in these technologies, you can further increase operational efficiency.

**Tip:** Consider enrolling in specialized CNC training programs for your employees to keep them updated on the latest techniques and industry standards.

The Ultimate Guide to Mastering CNC Cutting Techniques for Your Business Success

| Technique | Description | Material | Applications |

|---|---|---|---|

| Laser Cutting | Uses focused laser beams to cut materials with high precision. | Metals, Plastics, Wood | Sign making, Industrial parts, Decorative designs |

| Waterjet Cutting | Utilizes high-pressure water mixed with abrasives to cut through materials. | Metals, Glass, Stone | Aerospace, Automotive, Art, and Design |

| Plasma Cutting | Employs a plasma torch to cut through electrically conductive materials. | Steel, Aluminum, Copper | Metal fabrication, Construction, Repairs |

| CNC Milling | Cuts materials using rotating multi-point cutting tools. | Metals, Plastics, Wood | Machine parts, Prototyping, Custom designs |

| CNC Routing | A form of milling where the cutting tool moves along a fixed path. | Wood, Plastic, Composites | Furniture, Signage, Interior design |

Essential Equipment for CNC Cutting: Choosing the Right Tools for Your Business

When it comes to CNC cutting, selecting the right equipment is paramount to ensure efficiency and precision in your operations. The foundational tool in any CNC cutting setup is the CNC machine itself, and the decision between a router, laser, or plasma cutter largely depends on the materials you plan to work with. For instance, routers are ideal for wood and soft metals, while lasers provide unparalleled accuracy for thin materials like acrylic and fabric. Plasma cutters, on the other hand, excel in cutting through thick metal sheets, making them a go-to choice for heavy industrial applications.

In addition to the CNC machine, ancillary tools and accessories play a critical role in optimizing performance. Software for design and toolpath creation must be user-friendly yet powerful enough to handle complex projects. Investing in high-quality cutting tools, such as bits and nozzles, tailored to your machine type can drastically reduce wear and tear while enhancing cut quality. Furthermore, don’t overlook the importance of a robust dust collection system and proper safety gear, as these help maintain a clean workspace and keep operators safe from hazards. By carefully choosing the right tools and accessories, you can set your CNC cutting business up for success.

Step-by-Step Guide to Common CNC Cutting Techniques and Their Applications

Mastering CNC cutting techniques is essential for businesses looking to enhance their production capabilities and product offerings. In recent years, the integration of advanced technologies such as laser cutting and CNC machining has transformed how materials are processed. Laser cutting, in particular, allows for precise cutting and engraving, which can be seamlessly applied to various materials, including biomaterials for electronic applications. This not only improves efficiency but also enables the embedding of electronics directly into surfaces, paving the way for innovative product designs.

Furthermore, the emergence of artificial intelligence (AI) in CNC machining is revolutionizing precision manufacturing. AI-driven processes enhance the accuracy and efficiency of cutting techniques, enabling manufacturers to maintain high standards while reducing waste. By understanding common CNC cutting techniques and their applications, businesses can leverage these advancements to streamline operations, optimize production, and ultimately achieve greater success in the competitive landscape. Whether it's selective laser melting for additive manufacturing or sustainable practices in wood electronics, there is significant potential for growth and innovation in CNC cutting techniques.

Optimizing Your Workflow: Tips for Enhancing CNC Cutting Efficiency

When it comes to optimizing your workflow in CNC cutting, efficiency is paramount. One of the most effective ways to enhance productivity is by refining your setup process. This involves meticulously organizing tools, materials, and machine settings before commencing production. By reducing setup times and ensuring that all necessary components are readily available, businesses can significantly decrease downtime and maintain a consistent output.

Implementing a standard operating procedure for setup can further streamline this process, enabling operators to quickly adapt to different jobs without losing valuable time.

Another crucial aspect of improving CNC cutting efficiency is leveraging technology. Advanced software solutions not only assist in design but also offer insights into optimizing cutting parameters such as feed rates and tool paths. By utilizing simulation software, businesses can visualize and adjust the cutting process before actual production, minimizing waste and preventing costly mistakes.

Regular maintenance of CNC machines is equally important, as well-maintained equipment runs more reliably, reduces the risk of unexpected breakdowns, and ultimately enhances overall productivity. Investing in staff training to ensure operators are well-versed in both the machinery and the latest software tools can result in significant improvements in workflow efficiency.

Real-World Success Stories: How Businesses Transformed with CNC Cutting Techniques

CNC cutting techniques have revolutionized many industries by optimizing efficiency and precision. Businesses that have embraced these technologies often share remarkable success stories, showcasing how CNC cutting transformed their production processes and enhanced their bottom line. For instance, a small woodworking shop that once relied on manual cutting methods found a significant increase in output after integrating CNC machinery. This change not only allowed them to produce intricate designs that were previously unattainable but also reduced material wastage, thus improving profitability.

Another compelling example comes from a startup in the automotive sector. Faced with rising demand and limited resources, they turned to CNC cutting to streamline their manufacturing workflow. The ability to automate cutting and engraving reduced labor costs and sped up production times. As a result, they could expand their product offerings and enter new markets, gaining a competitive edge. These real-world examples underscore the transformative power of CNC cutting techniques, illustrating how thoughtful investment in technology can lead to substantial business success.

The Impact of CNC Cutting Techniques on Business Efficiency

Related Posts

-

Unlocking Precision in Cnc Cutting with Advanced Technical Specifications for Global Buyers

-

Revolutionizing Global Manufacturing Standards with Best Cnc Cutting from China

-

China Manufacturing Thrives Amidst US China Tariff Challenges with Best Cnc Milling Solutions

-

Global Trust in Quality Chinese Manufacturing for Best Multi Axis Machining Solutions

-

Exploring the 2025 Tech Revolution: Advantages of the Best CNC Turning Solutions

-

Cnc Turning vs Traditional Machining A Comprehensive Comparison Guide

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219