Cnc Turning vs Traditional Machining A Comprehensive Comparison Guide

In the ever-evolving landscape of manufacturing, the debate between CNC turning and traditional machining continues to capture the attention of industry leaders. A recent report by Grand View Research highlights that the global CNC machine market is projected to reach $117.45 billion by 2028, driven largely by the increased demand for precision and efficiency in production processes.

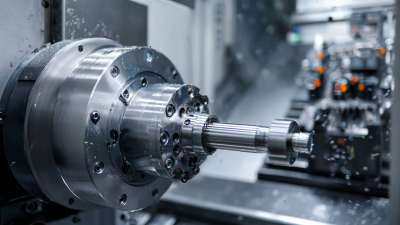

CNC turning, a process that utilizes computer-controlled lathes, offers unparalleled accuracy and speed, making it an attractive alternative to conventional machining methods. According to a 2021 study by Research and Markets, businesses adopting CNC technology can experience an increase in productivity by up to 30%, while minimizing errors and waste.

As manufacturers strive to meet the rising demand for high-quality components in sectors such as automotive and aerospace, understanding the distinctions between CNC turning and traditional machining becomes essential for making informed decisions that impact both operational efficiency and competitive edge.

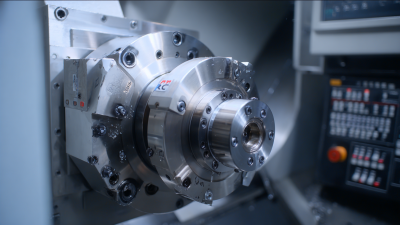

CNC Turning: Understanding the Basics and Applications

CNC turning is a modern machining technique that utilizes computer numerical control to create precise parts from various materials, including metals and plastics. According to a report by MarketsandMarkets, the CNC machine tools market is expected to reach $100 billion by 2025, driven by the rising demand for automation and the need for high-precision manufacturing. CNC turning allows for the efficient production of complex geometries and tight tolerances, making it an essential process in industries such as aerospace, automotive, and medical devices.

The versatility of CNC turning shines through its applications. For example, in the automotive sector, CNC lathes are extensively used to manufacture engine components, shafts, and custom fittings. A study from the National Institute of Standards and Technology underscores the advantages of CNC turning, reporting that automated machining can enhance productivity by up to 30% while significantly reducing waste. This high level of efficiency is a key factor driving manufacturers to transition from traditional machining methods to CNC applications, thereby addressing modern challenges in production and precision engineering.

Traditional Machining Methods: Techniques and Processes Explained

Traditional machining methods have been foundational in manufacturing, combining various techniques such as turning, milling, and grinding to create precision parts. Despite the rise of CNC technology, traditional machining continues to play a critical role due to its versatility and adaptability in different materials. Techniques like manual turning require skilled labor and offer unmatched craftsmanship, evidenced by the age-old adage, “Although the process is cumbersome, one must not spare effort; although the quality is expensive, one must not reduce the material resources.” This reminds us of the importance of quality in the production process.

While technology evolves rapidly, the essence of traditional machining lies in its techniques and processes. For example, a recent report predicts that the market for CNC machining centers will grow significantly, driven by demand in aerospace and automotive industries. Tips for manufacturers include investing in training for operators in both traditional and modern methods to optimize production quality and efficiency. Furthermore, integrating sustainable practices, such as recycling waste materials into feedstock for traditional machining, can enhance operational sustainability.

As advancements continue, combining traditional machining with innovations—such as high-performance cutting tools developed by research teams—can lead to improved outcomes. Embracing both methodologies allows manufacturers to harness the strengths of each approach while pushing boundaries in precision and quality.

CNC Turning vs Traditional Machining: A Comparative Analysis

This chart compares the efficiency, accuracy, and operational costs of CNC Turning versus Traditional Machining methods based on various factors.

Key Differences Between CNC Turning and Traditional Machining

CNC turning and traditional machining methods each offer distinct advantages and limitations in the manufacturing landscape. CNC turning utilizes automated processes driven by computer numerical control, enabling high precision, consistent quality, and the ability to produce complex geometries with ease. On the other hand, traditional machining relies on manual labor and basic machinery, which can be more flexible and less expensive for low-volume operations. The choice between these methods often depends on production scale, required precision, and material specifications.

**Tip:** When deciding between CNC turning and traditional machining, consider the batch size. For large-scale production, CNC turning may be more cost-effective due to its efficiency. In contrast, traditional machining could be preferable for small runs where setup costs are significant.

The integration of new technologies, such as 3D scanning and advanced predictive modeling, sets both types of machining apart in terms of capability. CNC machining can be programmed for complex tasks, while traditional methods often require skilled craftsmen for intricate designs.

**Tip:** Always assess the required tolerances and surface finish standards before choosing a machining method. If ultra-precision is not critical, traditional machining can offer faster turnaround times and may better suit smaller projects.

Benefits of CNC Turning Over Conventional Methods

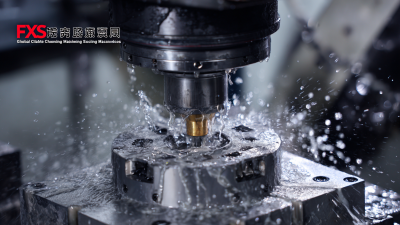

CNC turning offers several advantages over traditional machining methods, making it an increasingly popular choice in many manufacturing processes. One of the most significant benefits is the level of precision it provides. CNC machines can produce parts with incredibly tight tolerances, ensuring that each component meets exact specifications. This precision not only reduces waste but also enhances the overall quality of the finished product, allowing manufacturers to deliver superior items consistently.

Another key advantage of CNC turning is its efficiency. Unlike conventional machining, which often involves manual operation and adjustment, CNC machines can run continuously with minimal human intervention. This automation allows for faster production times and less downtime, enabling manufacturers to meet tight deadlines and increase output. Furthermore, modern CNC turning centers can handle complex geometries and perform multiple operations in a single setup, reducing the need for multiple machining processes and saving both time and resources. These factors combine to make CNC turning a highly effective option for businesses looking to streamline their manufacturing operations.

CNC Turning vs Traditional Machining: A Comprehensive Comparison Guide

| Feature | CNC Turning | Traditional Machining |

|---|---|---|

| Precision | High precision with tolerances up to ±0.005 mm | Moderate precision, typically ±0.01 mm |

| Production Speed | Faster production, can run continuously | Slower production, manual intervention needed |

| Setup Time | Short setup time, programmable | Longer setup time, requires manual adjustments |

| Material Versatility | Handles a wide range of materials | Limited to specific materials |

| Labor Costs | Lower labor costs due to automation | Higher labor costs due to manual operation |

| Waste Generation | Less waste, optimized for material usage | More waste, traditional cutting methods |

| Flexibility | Highly flexible, easy to change designs | Less flexible, significant retooling needed |

| Initial Investment | Higher initial investment for CNC machines | Lower initial investment, cheaper machines |

Choosing the Right Machining Method for Your Project Needs

When it comes to selecting the appropriate machining method for your project needs, the choice between CNC turning and traditional machining can significantly influence both the quality of the outcome and production efficiency. CNC turning employs computerized controls to execute precise and complex shapes, making it ideal for high-volume production runs. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, reflecting a growing trend toward automation and precision in manufacturing.

In contrast, traditional machining still holds its ground for certain applications, particularly where smaller production runs or unique customizations are required. Traditional methods often require more manual intervention, which can be advantageous for bespoke projects that demand intricate craftsmanship. The American Society of Mechanical Engineers indicates that while CNC turning can offer a reduction in labor costs by up to 40%, traditional methods might still provide greater flexibility for specialized jobs. By assessing specific project requirements and production scales, businesses can better determine which machining method aligns with their operational goals.

Related Posts

-

Exploring the 2025 Tech Revolution: Advantages of the Best CNC Turning Solutions

-

Setting New Industry Standards with the Best Cnc Turning Machine

-

Unlocking Precision in Cnc Cutting with Advanced Technical Specifications for Global Buyers

-

China Manufacturing Thrives Amidst US China Tariff Challenges with Best Cnc Milling Solutions

-

Revolutionizing Global Manufacturing Standards with Best Cnc Cutting from China

-

Global Trust in Quality Chinese Manufacturing for Best Multi Axis Machining Solutions

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219