Cnc Turning Milling Essential Checklist for Optimizing Your Production Process

In the fast-paced world of manufacturing, optimizing production processes is paramount for maintaining a competitive edge. CNC turning milling has emerged as a cornerstone of precision machining, with the global CNC machine market expected to reach $100 billion by 2025, according to a report by MarketsandMarkets. This rapid growth underscores the importance of efficient CNC turning milling techniques in enhancing productivity and reducing operational costs. Companies that leverage cutting-edge CNC technology not only improve their workflow but also ensure higher quality outputs, with reports indicating that precision machining can increase manufacturing efficiency by up to 30%. This ultimate guide will provide an essential checklist to help businesses harness the full potential of CNC turning milling, fostering innovation and sustainability in their production processes.

Understanding CNC Turning and Milling: Key Benefits for Precision Manufacturing

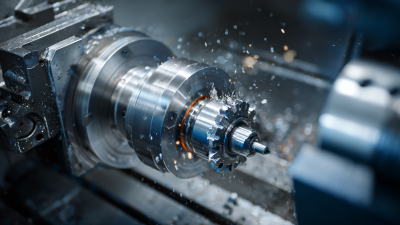

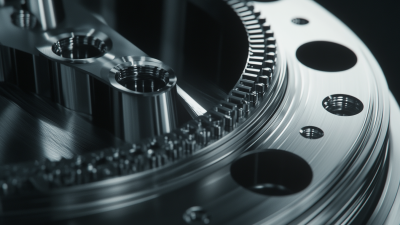

CNC turning and milling are indispensable techniques in the realm of precision manufacturing. These processes allow for the creation of complex geometries and high-tolerance components that are essential in industries such as aerospace, automotive, and medical device manufacturing. CNC (Computer Numerical Control) technology enhances traditional machining methods by providing increased accuracy, repeatability, and efficiency, which is crucial for meeting the ever-growing demands for high-quality parts.

One of the primary benefits of CNC turning is its ability to produce cylindrical parts with a smooth finish and precise measurements. This process removes material from a workpiece by rotating it against a cutting tool, making it ideal for items like shafts, bolts, and gears. On the other hand, CNC milling offers versatility by allowing for the machining of various shapes and features through the use of rotating cutting tools. The combination of these techniques in a manufacturing setup can significantly optimize production times while minimizing waste, leading to overall cost savings and enhanced competitiveness in the market. Embracing CNC turning and milling not only improves operational efficiency but also elevates the standard of quality in precision manufacturing.

Enhancing Production Efficiency: How CNC Techniques Improve Output and Reduce Waste

CNC (Computer Numerical Control) techniques have revolutionized manufacturing by enhancing production efficiency and minimizing waste. According to a report from the International Data Corporation, CNC machining can improve productivity by up to 30%, allowing manufacturers to produce higher volumes without significantly increasing operational costs. This efficiency is largely attributed to the precision and repeatability of CNC machines, which reduce human error and ensure every component is made to exact specifications.

Moreover, the adoption of CNC turning and milling technologies can lead to significant material savings. The National Institute of Standards and Technology (NIST) notes that poor machining practices can cause material waste levels of up to 20%, a figure that can be drastically cut with the use of advanced CNC methods. By optimizing tool paths and conducting simulations before production, companies can minimize scrap rates and enhance resource utilization. As a result, businesses not only boost their output but also contribute to sustainability goals by lowering excessive material consumption.

Cost-Effectiveness of CNC Turning and Milling: Analyzing Return on Investment

When considering the cost-effectiveness of CNC turning and milling, it's crucial to analyze the return on investment (ROI) these technologies can offer. CNC machining allows for high precision and repeatability, which translates into less material waste and lower labor costs. By automating the turning and milling processes, manufacturers can significantly reduce production times, leading to quicker turnaround on products. This efficiency not only boosts output but also enhances profitability, allowing businesses to respond swiftly to market demands.

Moreover, the initial investment in CNC machinery often pays off over time as operational costs decrease. Companies that implement CNC turning and milling can lower their long-term expenditures through reduced scrap rates and improved energy efficiency. The ability to switch between different projects with minimal downtime also allows for greater flexibility, enabling manufacturers to diversify their product offerings without incurring heavy costs associated with traditional methods. Ultimately, analyzing the ROI of CNC technologies is essential for businesses aiming to optimize their production process while maintaining cost-effectiveness.

Quality Control in CNC Operations: Ensuring Consistency Through Advanced Technologies

In the realm of CNC operations, quality control is paramount. A recent report by the Society of Manufacturing Engineers underscores that over 55% of manufacturers cite consistency in production quality as a critical factor impacting their competitiveness. Advanced technologies such as laser scanning and automated inspection systems are proving essential in maintaining this consistency. These methods not only reduce human error but also enhance precision in measurements, ensuring that every component meets stringent quality standards.

Moreover, implementing real-time monitoring solutions can lead to significant improvements in compliance rates. According to a study by the National Institute of Standards and Technology, companies that adopted advanced monitoring technologies saw a 30% reduction in defects. Such innovations not only streamline the quality assurance process but also facilitate immediate adjustments during production, thereby minimizing downtime and wastage. By leveraging these advanced tools, manufacturers can achieve not only heightened precision but also foster a culture of continuous improvement, ultimately driving productivity and profitability in CNC operations.

CNC Turning and Milling Quality Control Metrics

Innovative Solutions in CNC Machining: Adapting to Market Trends and Customer Needs

In today's fast-evolving manufacturing landscape, CNC machining stands at the forefront of innovation, driven by the need to adapt to market trends and customer demands. The global CNC machine market, projected to reach approximately USD 24 billion by 2032, has been significantly shaped by the digitalization of manufacturing processes, which enhances productivity and efficiency across a wide array of industries. Embracing advanced technologies such as artificial intelligence and IoT is no longer optional; it’s essential for maintaining competitiveness.

Moreover, the shifting market dynamics are reflected in the increasing adoption of flexible manufacturing systems, including modular machine designs that support rapid reconfiguration. The Builders Joinery and Carpentry of Wood Market is on track to grow from USD 115.46 billion in 2024 to USD 150 billion by 2035, highlighting the transformative impact of adaptable production methods. As companies look to streamline operations and optimize workflows, incorporating innovative CNC solutions that respond to customer needs becomes crucial for long-term success.

The evolution of CNC technology promises further advancements, such as 3D printing integration, elevating the capabilities and efficiency of modern manufacturing processes.

Related Posts

-

7 Insider Secrets for Sourcing High Quality Cnc Turning Parts Globally

-

Understanding the Advantages of CNC Milling and Turning Applications for Diverse Industries

-

How to Identify Top Manufacturers for Best CNC Milling Solutions Globally

-

China Manufacturing Thrives Amidst US China Tariff Challenges with Best Cnc Milling Solutions

-

5 Essential Tips to Optimize Your CNC Turning and Milling Processes for Better Efficiency

-

How to Identify Top Tier Precision CNC Machining Suppliers for Your Manufacturing Needs

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219