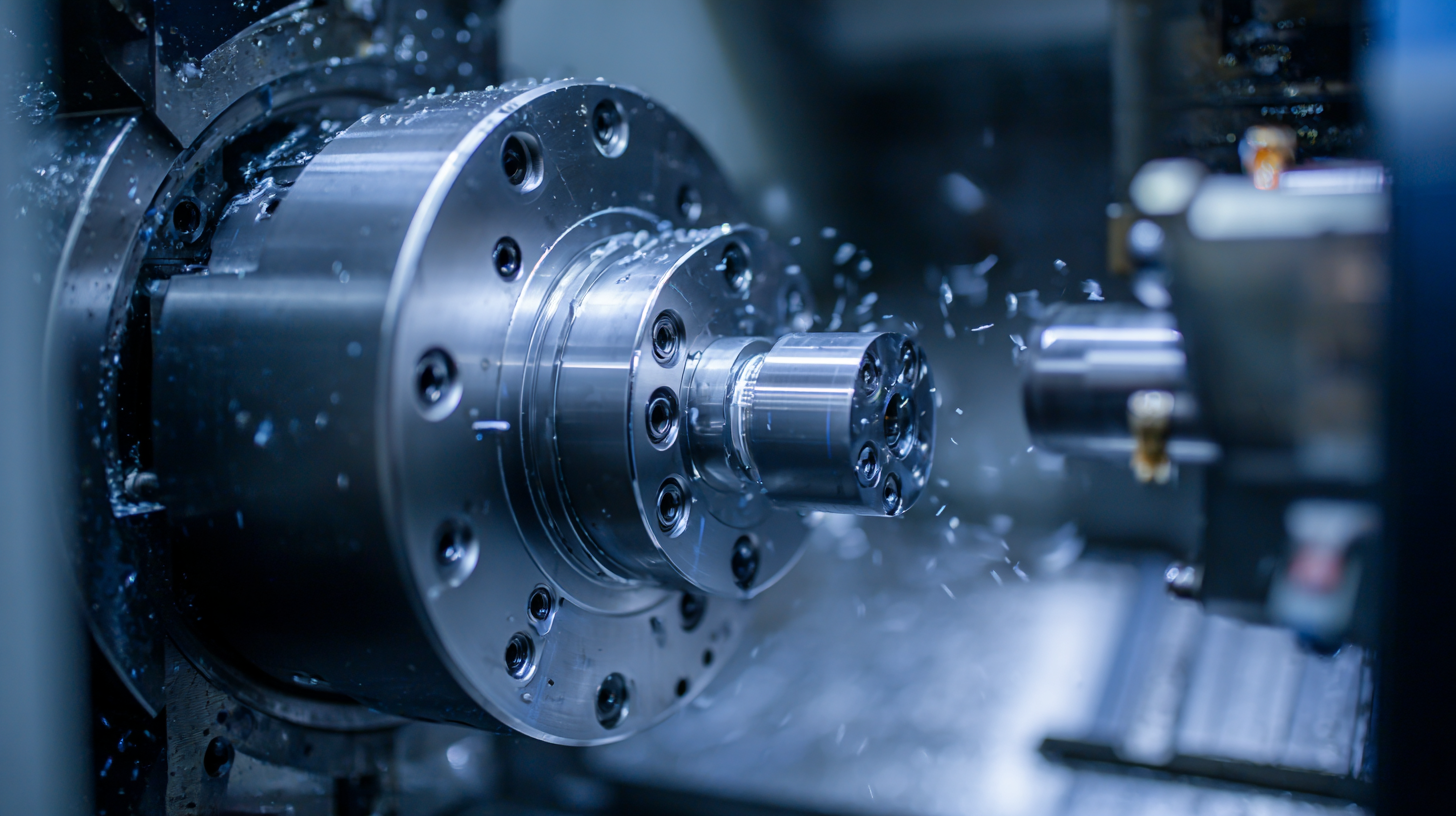

Unlocking Precision: How CNC Machining Transforms Custom Manufacturing

In today's competitive landscape, the demand for precision and customization in manufacturing has never been greater. CNC machining has emerged as a pivotal technology, revolutionizing the way products are designed and produced. According to a report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2025, growing at a compound annual growth rate (CAGR) of

6.2%. This surge underscores the industry’s shift towards more efficient and versatile manufacturing processes. CNC machining enables manufacturers to produce complex geometries with remarkable accuracy and repeatability, significantly reducing lead times and material waste. As industries—from aerospace to healthcare—seek to leverage personalized solutions without sacrificing quality, the transformation brought about by CNC machining is not just beneficial; it is essential for thriving in the era of digital manufacturing.

In today's competitive landscape, the demand for precision and customization in manufacturing has never been greater. CNC machining has emerged as a pivotal technology, revolutionizing the way products are designed and produced. According to a report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2025, growing at a compound annual growth rate (CAGR) of

6.2%. This surge underscores the industry’s shift towards more efficient and versatile manufacturing processes. CNC machining enables manufacturers to produce complex geometries with remarkable accuracy and repeatability, significantly reducing lead times and material waste. As industries—from aerospace to healthcare—seek to leverage personalized solutions without sacrificing quality, the transformation brought about by CNC machining is not just beneficial; it is essential for thriving in the era of digital manufacturing.

Understanding CNC Machining: The Basics of Computer Numerical Control

CNC machining, or Computer Numerical Control machining, has revolutionized the landscape of custom manufacturing. This technology allows for precise control of complex machinery through computer programming, enabling manufacturers to produce parts with remarkable accuracy and repeatability. According to a report by Markets and Markets, the global CNC machining market is expected to reach $100 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth is driven by the increasing demand for precision engineering in various sectors, including aerospace, automotive, and healthcare.

CNC machining, or Computer Numerical Control machining, has revolutionized the landscape of custom manufacturing. This technology allows for precise control of complex machinery through computer programming, enabling manufacturers to produce parts with remarkable accuracy and repeatability. According to a report by Markets and Markets, the global CNC machining market is expected to reach $100 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth is driven by the increasing demand for precision engineering in various sectors, including aerospace, automotive, and healthcare.

One of the key benefits of CNC machining is its ability to produce intricate designs that would be challenging or impossible to achieve using traditional methods. The use of advanced materials and state-of-the-art software allows manufacturers to optimize their processes, reducing waste and lead times. For instance, a 2021 survey by the National Association of Manufacturers revealed that 69% of manufacturers reported adopting CNC technology to enhance their production capabilities.

Tip: To fully leverage the advantages of CNC machining, businesses should invest in training their workforce on the latest CNC programming techniques. Staying updated with software advancements can significantly improve operational efficiency.

In conclusion, the fundamentals of CNC machining lay the groundwork for innovations in custom manufacturing. As technology continues to evolve, integrating smart manufacturing practices will further amplify the benefits of CNC machining, propelling industries into a new era of production excellence.

Tip: Regular maintenance of CNC machines is crucial for maintaining precision and prolonging machine life. Implementing a routine check can prevent costly downtimes and ensure consistent performance.

The Impact of CNC Machining on Custom Manufacturing Processes

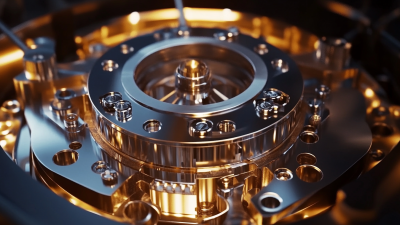

The impact of CNC machining on custom manufacturing processes is profound, particularly as companies increasingly turn to advanced technologies such as artificial intelligence (AI) to enhance precision and efficiency. According to recent market research, the CNC machines market is projected to reach USD 170.4 billion by 2033, growing at a compound annual growth rate (CAGR) of 9.80% from its current valuation of USD 66.9 billion in 2023. This growth highlights the increasing reliance on CNC machining for producing high-quality and complex components across various industries.

AI-driven CNC machining is revolutionizing traditional manufacturing approaches by optimizing workflows, reducing lead times, and minimizing waste. As specialty forgers begin to leverage these innovations, they can produce custom, seamless rolled rings and complex forged parts with greater accuracy and in shorter timeframes. The adoption of such technologies not only streamlines operations but also positions manufacturers to better meet the evolving demands of custom fabrication, ultimately driving a more sustainable and efficient production landscape.

Key Advantages of CNC Machining in Precision Engineering

CNC machining has revolutionized custom manufacturing by offering unparalleled precision and efficiency. One of the key advantages of CNC technology in precision engineering is its ability to produce complex components with exact specifications, reducing the margin for error significantly. This high level of accuracy not only ensures the quality of the products but also enhances the productivity of the manufacturing process. As industries increasingly demand intricate designs and quick turnaround times, CNC machining stands out by enabling rapid prototyping that meets these expectations.

Furthermore, the growing market for CNC machines reflects the rising importance of precision engineering across various sectors. With projections indicating substantial growth—from $101.22 billion in 2025 to $195.59 billion by 2032—it's evident that businesses are investing in advanced technologies to maintain a competitive edge. This trend underlines the significance of incorporating CNC machining into manufacturing strategies, as it not only meets today’s demands for speed and accuracy but also prepares companies for future challenges in production efficiency and innovation.

Comparative Analysis: CNC Machining vs. Traditional Manufacturing Methods

CNC machining has revolutionized custom manufacturing by offering unparalleled precision compared to traditional methods like manual machining and fabrication. Traditional manufacturing often relies on human skill and experience, which can lead to variability in quality and longer production times. In contrast, CNC machining utilizes computer-controlled equipment to follow exact specifications, ensuring consistent quality and rapidly replicating complex designs. This technological advantage not only minimizes errors but also significantly reduces material waste.

Tips: To maximize the benefits of CNC machining in your projects, consider investing in high-quality CAD software to design your parts accurately. Additionally, thoroughly assess your material selection, as the right choice can enhance the machining process and overall end product.

When comparing CNC machining to traditional methods, another significant advantage is the flexibility it offers. CNC machines can be quickly reprogrammed to accommodate different designs without the need for extensive manual adjustments. This adaptability allows manufacturers to respond swiftly to market demands and innovate faster than ever before. Embracing CNC machining can streamline operations and improve the ability to deliver customized solutions tailored to specific client needs.

Tips: Always keep communication open with your machining service provider to ensure they fully understand your specifications. Utilizing prototypes during development can also help in identifying design flaws early in the process, leading to a more efficient manufacturing cycle.

Unlocking Precision: CNC Machining vs. Traditional Manufacturing Methods

Future Trends in CNC Machining and Custom Manufacturing Solutions

As CNC machining continues to evolve, it is increasingly integrating with Industry 4.0 technologies, which enhances both precision and sustainability in custom manufacturing. The adoption of artificial intelligence and the Industrial Internet of Things (IIoT) is reshaping how manufacturers operate, allowing for real-time data collection and analysis. This integration ensures that production processes are not only more efficient but also more responsive to market demands, positioning CNC services as a crucial player in the resurgence of the UK’s manufacturing sector. According to industry reports, the precision turned product manufacturing market is projected to reach USD 196.11 billion by 2034, signaling robust growth fueled by innovations in custom solutions.

Tips: For businesses looking to harness CNC machining, consider investing in advanced machining centers equipped with smart capabilities. These investments can drastically improve production timelines and reduce waste, supporting more sustainable practices. Additionally, exploring profitable CNC projects that are forecasted to be in high demand—such as custom components for agricultural machinery—can also help enhance both creativity and profitability in your operations. With North America’s contract manufacturing services market expected to grow significantly, tapping into these trends will be vital for future success in the field.

Related Posts

-

Unlocking Precision: The Future of Cnc Machine Multi Axis for Global Manufacturers

-

Discovering Reliable Suppliers with Effective Strategies for Cnc Machining Success

-

Emerging Trends in Precision CNC Machining for Global Buyers in 2025 and Practical Strategies to Leverage Them

-

Understanding the Advantages of CNC Milling and Turning Applications for Diverse Industries

-

Understanding Industry Production Standards for the Best Multi Axis Cnc Milling Machine

-

How to Optimize Your CNC Milling Machining Process for Maximum Efficiency

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219