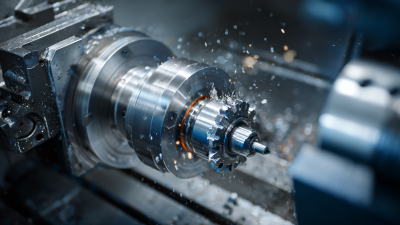

How to Choose the Best Cnc Parts Machining Service for Your Project

Choosing the right CNC parts machining service is crucial for the success of any manufacturing project. With the rapid advancement of technology and the increasing complexity of projects, it becomes essential to partner with a service provider that not only understands your specific requirements but also delivers precision and quality. When evaluating potential CNC parts machining services, consider factors such as their experience, technological capabilities, turnaround times, and customer support. Additionally, assess their quality assurance processes and past client testimonials to gauge their reliability. This guide aims to provide you with a comprehensive understanding of how to identify the best CNC parts machining service that aligns with your project needs, ultimately ensuring optimal results and efficient workflow.

Understanding Your Project Requirements for CNC Parts Machining

When embarking on a project that requires CNC parts machining, understanding your project requirements is crucial. Whether you are opting for FDM 3D printing in PLA or CNC machining in walnut, each method has unique characteristics influencing the design and production process. For FDM 3D printing, consider the geometric complexity, surface finish, and functional requirements. This approach allows for intricate designs, making it suitable for prototypes or less load-bearing applications.

On the other hand, CNC machining in walnut offers durability and a refined finish, ideal for parts needing strength and aesthetic appeal. This method requires a careful selection of tolerances and dimensions to ensure precision.

Tips:

- Clearly define the functionality of the part to determine the appropriate material and manufacturing method.

- Collaborate with your machining service provider to align your design specifications with their capabilities, ensuring a seamless production process.

- Always factor in lead time and costs associated with each manufacturing method to select the best option for your timeline and budget.

Evaluating CNC Machining Service Providers: Key Factors to Consider

When evaluating CNC machining service providers, several key factors must be considered to make an informed decision. First and foremost, the provider's experience and expertise in handling specific materials and complex geometries can significantly impact the quality of your final product. According to a recent industry report by Technavio, the global CNC machining market is expected to grow by over 8% annually through 2026, indicating a rising demand for high-quality machining services. Choosing a provider with proven experience in your specific industry can ensure that they have the knowledge necessary to meet your project's unique requirements.

Additionally, assessing the technological capabilities of potential CNC machining partners is crucial. Providers that utilize advanced machinery, such as multi-axis CNC machines, can offer improved precision and efficiency. A study by MarketsandMarkets highlights that automation in CNC machining can lead to a 30% increase in operational efficiency. Evaluating the types of technologies and software that a service provider employs will give you insight into their ability to produce intricate parts while maintaining high standards of quality. This, combined with a robust quality assurance process, is vital for ensuring that your project will meet industry standards and specifications.

Assessing the Quality and Precision of CNC Machined Parts

When selecting a CNC parts machining service, understanding the quality and precision of the machined parts is crucial. High-precision CNC machining services typically offer tolerances as tight as ±0.001 inches, making them suitable for industries such as aerospace, automotive, and medical. According to a recent industry report by MarketsandMarkets, the global CNC machining market is expected to reach $117 billion by 2026, indicating a growing demand for high-quality machined components. Evaluating a provider's capabilities in delivering precision can significantly impact the overall success of your project.

**Tips:** When assessing a CNC machining service, request samples of their previous work, specifically focusing on tolerances and surface finish. Certification such as ISO 9001 can also serve as an indicator of a company's commitment to quality management practices.

Quality assurance should also include evaluating the materials used in the machining process. It is essential to know whether the service can work with various materials, including metals and plastics, while maintaining integrity and performance. Industry standards, such as ASTM and ASME, can provide guidance on the specifications required for your specific application. Maintaining quality control throughout the production process not only ensures consistency but also prevents costly delays in project timelines.

**Tips:** Inquire about the machining service's inspection protocols and any quality control technologies they employ, such as CMM (Coordinate Measuring Machines) to ensure precision throughout manufacturing.

Quality Assessment of CNC Machined Parts

This chart presents a quality assessment of CNC machined parts based on several key criteria, including Dimensional Accuracy, Surface Finish, Material Quality, Processing Time, and Cost Effectiveness. The scores range from 0 to 100, indicating how well the parts meet each criterion.

Comparing Pricing and Turnaround Times for CNC Machining Services

When selecting a CNC parts machining service, comparing pricing and turnaround times is essential to ensure that your project remains within budget and meets deadlines.

According to the 2023 report by the International Federation of Robotics (IFR), the average cost for CNC machining services ranges from $50 to $150 per hour,

depending on the complexity of the design and materials used. This variance in pricing reflects the expertise required and the technology employed in the machining process.

Therefore, it's prudent to obtain multiple quotes from different service providers to identify competitive rates that align with your project specifications.

Turnaround times in CNC machining can significantly impact production schedules. A survey conducted by the Custom Manufacturing & Fabrication Association indicated that 70% of manufacturers prioritize quick delivery,

with an average lead time of just 5-10 days for standard projects. However, for intricate designs or low-volume runs, this can extend to several weeks.

It is vital to clearly communicate your timelines with potential machining partners and inquire about their capabilities in meeting urgent requests.

By carefully evaluating both pricing and turnaround times, you can make a well-informed decision that supports the success of your project.

Looking for Customer Reviews and Recommendations in CNC Machining

When selecting a CNC parts machining service, customer reviews and recommendations play a crucial role in ensuring you make the right choice. To gather useful insights, start by exploring popular review platforms, such as Google Reviews and Yelp. Pay attention to both positive and negative feedback, as well-rounded insights will help you gauge the reliability and quality of service offered by different providers. Additionally, consider reaching out to industry peers or forums where professionals discuss their experiences with specific machining services.

Tips for evaluating customer reviews include looking for consistent themes in feedback. If multiple clients mention similar issues (or praises), it’s likely a reliable indicator of what to expect. Also, consider the overall rating, but don’t overlook the context behind each review. Factors like timely communication, adherence to deadlines, and quality of the final product can greatly impact your project's success. Finally, don’t hesitate to ask potential service providers for references. A reputable company should have no problem providing contacts of previous clients who can vouch for their work.

Related Posts

-

The Definitive Ultimate Guide to Mastering Axis CNC Machines for Your Business Success

-

Ultimate Guide to Maximizing Efficiency with Axis CNC Machines in Your Workshop

-

Choosing the Right Manufacturer for Best Cnc Parts and Tailored Solutions for Your Needs

-

Revolutionizing Global Supply Chains with Advanced CNC Parts Machining Technologies

-

The Evolution of Cnc Machining Parts in Global Manufacturing

-

5 Essential Tips to Optimize Your CNC Turning and Milling Processes for Better Efficiency

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219