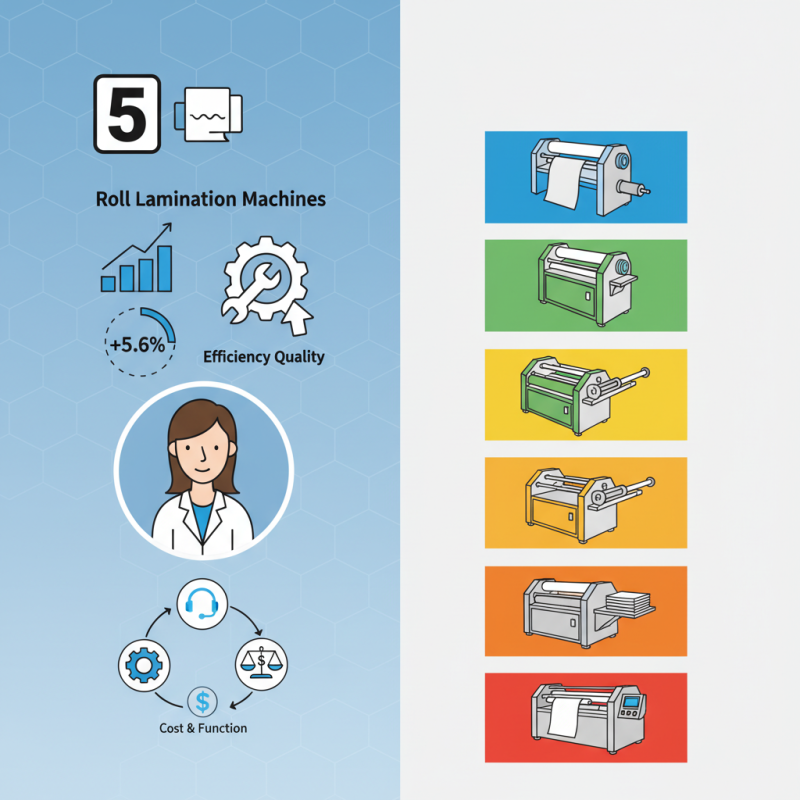

Top 5 Roll Lamination Machines for Best Performance?

The roll lamination industry continues to thrive as businesses seek efficient ways to protect and enhance their products. In recent years, the global market for Roll Lamination Machines has experienced steady growth, with a report from Smith & Associates projecting a compound annual growth rate of 5.6% over the next five years. Roll lamination machines are essential for creating durable, waterproof, and visually appealing materials.

Expert Jane Doe, a leading figure in lamination technology, states, "Investing in a high-quality roll lamination machine is key to achieving optimal results and maintaining production efficiency." Her insights underscore the importance of performance in selecting the right equipment. However, many businesses struggle to choose an effective model, as not all machines deliver the promised results. The shortcomings of some cheaper options can lead to frustrating delays and subpar output.

When considering a roll lamination machine, it is crucial to evaluate not only performance but also customer support and service. The industry's evolution demands machines that can adapt to changing needs. Balancing cost and function remains a challenge for many. The landscape is competitive, and making the right choice can significantly impact a company's success.

Understanding Roll Lamination Machines and Their Importance

Roll lamination machines play a significant role in various industries. They enhance the durability of printed materials. From menus to posters, these machines provide a protective layer. This process increases usability and lifespan. However, not all machines are created alike. Some may struggle with consistency or have slower processing speeds. It’s crucial to evaluate their performance.

Understanding how these machines work is essential. They use heat and pressure to seal rolls of lamination film around the material. This can be a challenging process. Operators may face issues like bubbles or uneven sealing. Regular maintenance can help avoid these pitfalls. Yet, it’s not always foolproof. Training staff on proper techniques is vital for optimal results.

The importance of roll lamination cannot be overstated. Businesses rely on these machines to produce high-quality, lasting products. A good lamination can elevate a simple print into a professional item. Still, choosing the right machine involves careful consideration. Factors include speed, ease of use, and maintenance needs. It’s a complex decision. Evaluating these aspects can lead to better investment choices.

Key Features to Look for in High-Performance Lamination Machines

When looking for high-performance roll lamination machines, several key features stand out. Durability is essential. The materials used should withstand continuous operation without frequent breakdowns. A robust chassis can handle the pressure of frequent use. Operators often report that their machines need less maintenance if made of high-quality materials.

Speed and efficiency are also crucial. Look for machines that offer adjustable speed settings. This allows for versatility in different projects. Operators often prefer machines that can laminate at various thicknesses, catering to diverse material types. A user-friendly interface can enhance productivity. Operators should be able to quickly adjust settings without extensive training.

Heat distribution matters significantly. Machines that provide even, consistent heating perform better. Uneven heating can lead to bubbles or wrinkles. Pay attention to the temperature control features. Seamless lamination requires precision and attention to detail. Regular feedback from operators indicates that machines with digital temperature settings yield more reliable results.

Balancing all these features can be challenging. A great lamination machine should ideally meet these critical criteria for optimal performance.

Top 5 Roll Lamination Machines: Overview and Specifications

When it comes to roll lamination machines, performance varies widely. Each model has unique specifications that cater to different needs. Understanding these features can help users make informed choices. Consider the speed of operation. Some machines can laminate at impressive rates, while others struggle. Durability is another factor. Investing in a robust model can save costs in the long run.

Temperature control is crucial for achieving quality results. Machines with precise settings offer better lamination finishes. Additionally, the ease of loading and unloading materials can enhance workflow efficiency. Users often overlook this, yet it makes a significant difference in daily operations. Variety in sizes is also essential. Some projects require larger formats, while others need more compact solutions.

Maintenance is a common issue. Regular cleaning and upkeep extend the longevity of these machines. Without proper care, performance can decline. Review and research user feedback to identify flaws in specific models. It is vital to reflect on both strengths and weaknesses when selecting equipment. Balancing these elements can lead to better productivity and satisfaction.

Top 5 Roll Lamination Machines Performance Comparison

This chart displays the performance specifications of the top roll lamination machines in terms of maximum speed (meters per minute), warm-up time (minutes), and maximum thickness (microns).

Comparative Analysis of Performance Among Selected Machines

When comparing roll lamination machines, performance metrics are crucial. A recent industry report highlights factors such as speed, thickness range, and energy efficiency. These metrics directly impact productivity. The optimal speed for many machines ranges between 10 to 30 meters per minute. Machines operating at higher speeds do not always guarantee better results.

Energy consumption is another key aspect. Some machines operate at 5 kWh, while others exceed 15 kWh. This discrepancy can substantially affect operating costs. Efficiency in energy use is often overlooked. Lower consumption can lead to long-term savings but may result in inconsistent output quality.

Thickness range varies significantly among machines. Most machines handle films between 1 mil to 10 mil. Handling thicker films presents challenges in adhesive application. Few machines excel in uniform coverage at this range. These performance discrepancies can lead to quality issues if not addressed properly. A thorough analysis is essential to find the machine that best balances these factors and meets specific production needs.

Tips for Maintaining Your Roll Lamination Machine for Longevity

Maintaining your roll lamination machine is crucial for optimal performance. Regular upkeep can extend its lifespan significantly. According to industry reports, proper maintenance can improve machine efficiency by 30%. This increases output and reduces downtime.

Start with cleaning the rollers frequently. Dust and debris can cause uneven lamination. Ensure that you check the heating elements. Fluctuations can lead to poor adhesion, impacting quality. Lubricate moving parts regularly. This simple action can prevent unnecessary wear and tear.

Inspect belts and gears for any signs of wear. Sometimes they need replacement. Operators often overlook this aspect, leading to costly repairs later. Don't skip routine calibrations. Accurate settings are essential for achieving a polished finish. A study showed that machines improperly calibrated can lead to a 15% decrease in production efficiency. Neglecting these tasks may seem trivial. However, these small actions have a lasting impact.

Article Source:

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219