How to Optimize Your CNC Milling Machining Process for Maximum Efficiency

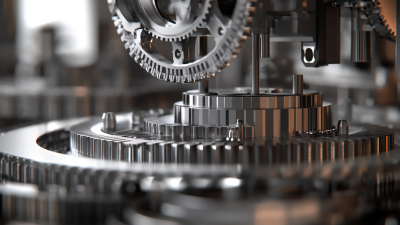

The CNC milling machining process is a cornerstone of modern manufacturing, accounting for approximately 20% of the global machine tool market. As industries increasingly demand precision and efficiency, optimizing CNC milling operations has never been more critical. According to a recent report by Market Research Future, the global CNC machining market is expected to reach over $100 billion by 2025, underscoring the need for manufacturers to enhance their processes to remain competitive.

Efficiency in CNC milling machining not only reduces production time but also minimizes waste and operational costs, leading to improved profitability. By employing strategic optimization techniques such as adaptive machining, tool path optimization, and advanced equipment integration, businesses can significantly boost their output and reliability.

This article explores essential strategies to optimize your CNC milling machining process, ensuring maximum productivity and cost-effectiveness in today's fast-paced industrial landscape.

Strategies for Reducing Cycle Time in CNC Milling Operations

Reducing cycle time in CNC milling operations is essential for maximizing efficiency and productivity. One effective strategy is to optimize tool selection and feed rates. Choosing high-performance cutting tools that match the material being machined can significantly enhance processing speed. Additionally, adjusting feed rates to the optimal levels for each specific operation can prevent bottlenecks and improve overall output.

**Tips:** Always refer to the manufacturer’s guidelines for tool parameters. Conducting test cuts can help determine the best settings before full-scale production.

Another vital approach is to streamline the setup process. Implementing quick-change tooling systems and organizing workspaces strategically can drastically cut down on downtime. Efficient changeover protocols, such as pre-assembling tools and fixtures, enable operators to switch between tasks swiftly without sacrificing precision.

**Tips:** Maintain an organized inventory of tools and parts to minimize search time. Regularly schedule maintenance checks to ensure that all equipment is functioning properly, as less downtime translates to faster cycle times.

Optimization of CNC Milling Cycle Time

This bar chart illustrates the various components of cycle time in the CNC milling machining process. By analyzing and optimizing these individual segments, operators can significantly enhance overall efficiency.

Leveraging Advanced Tooling Techniques for Enhanced Machining Efficiency

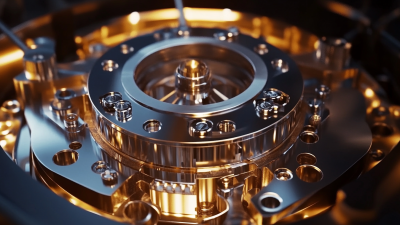

The integration of advanced tooling techniques in CNC milling is pivotal for maximizing machining efficiency. With the advent of digital manufacturing technologies, manufacturers can now leverage sophisticated tools that not only enhance productivity but also reduce operational costs. Innovations such as high-speed cutting methods, coupled with improved cutting fluids, allow for increased precision and decreased wear on tools, thus extending tool life and minimizing downtime.

Furthermore, the emphasis on sustainable machining practices cannot be overlooked. The utilization of eco-friendly cutting fluids and the evolution of advanced engineering materials play a critical role in reducing environmental impacts while maintaining superior machining quality. By adopting these advanced techniques, manufacturers can achieve enhanced performance, ensuring compliance with health and safety regulations while also contributing to a more sustainable manufacturing ecosystem. The continuous investment in technology and tooling innovation is essential for staying competitive in the ever-evolving landscape of CNC machining.

How to Optimize Your CNC Milling Machining Process for Maximum Efficiency - Leveraging Advanced Tooling Techniques for Enhanced Machining Efficiency

| Parameter | Value | Comments |

|---|---|---|

| Spindle Speed (RPM) | 12000 | Optimal for aluminum machining |

| Feed Rate (in/min) | 45 | Maximized for efficiency |

| Tool Material | Carbide | Durability and wear resistance |

| Cutting Depth (in) | 0.1 | Minimized for better control |

| Tool Path Strategy | Adaptive | Reduces air cutting time |

| Coolant Type | Mist Coolant | Improves chip removal |

| Tool Life (hours) | 8 | Regular monitoring required |

Implementing Automation Solutions to Streamline CNC Milling Processes

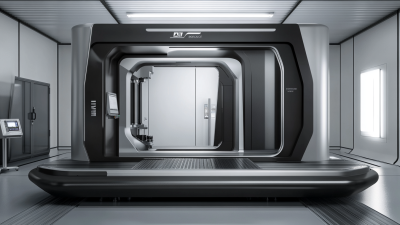

In the quest for maximum efficiency in CNC milling processes, implementing

automation solutions is pivotal. Automation technologies in manufacturing

not only enhance operational efficiency but also improve precision and adaptability. For instance, the global CNC

machine market is projected to grow from $101.22 billion in 2025 to

$195.59 billion by 2032, reflecting a compound annual growth rate (CAGR)

of 9.9%. This growth is driven by innovations in automation that

streamline workflows and reduce production downtime.

Tips for optimizing your CNC milling processes include adopting predictive maintenance systems

that leverage AI to foresee potential machine failures, thus minimizing interruptions. Additionally, integrating

advanced CAM software can enable better programming and more efficient machining setups, leading to reduced lead

times and improved product quality. As industries increasingly pivot towards automation, staying abreast of the

latest technology trends is essential for enhancing competitive advantage.

Furthermore, incorporating automated programming solutions can lead to significant time savings in setup and

machining processes, allowing manufacturers to respond more swiftly to market demands. Transitioning to a

more automated environment can not only enhance productivity but also contribute to a sustainable manufacturing

approach through reduced waste and energy consumption.

Analyzing Material Removal Rates to Maximize CNC Milling Performance

To maximize the performance of CNC milling, it’s crucial to thoroughly analyze material removal rates (MRR), which is the volume of material removed per unit of time. According to a report by the International Journal of Advanced Manufacturing Technology, optimizing MRR can lead to increased productivity and reduced manufacturing costs by as much as 30%. By focusing on the cutting parameters such as spindle speed, feed rate, and depth of cut, manufacturers can significantly enhance their machining processes.

For example, research from the Michigan Manufacturing Technology Center indicates that increasing the feed rate while maintaining adequate spindle speed can boost MRR without compromising component integrity. In practical applications, a feed rate increase of just 20% has shown to lift MRR values from 10 cubic centimeters per minute to 12 cubic centimeters per minute, translating into faster production times and higher throughput. Additionally, utilizing advanced tooling materials, such as carbide or ceramic inserts, can further improve MRR and tool life, leading to more cost-effective machining operations. Emphasizing these metrics can help manufacturers streamline their CNC milling processes for optimal efficiency.

Integrating Industry 4.0 Technologies in CNC Milling for Optimal Resource Utilization

Integrating Industry 4.0 technologies into CNC milling processes can significantly enhance resource utilization and overall efficiency. Recent studies suggest that the adoption of IoT (Internet of Things) in manufacturing can lead to a reduction in production costs by as much as 20%. By employing smart sensors and connectivity solutions, manufacturers can monitor equipment performance in real-time, enabling predictive maintenance that minimizes downtime and optimizes machine usage.

Moreover, the use of advanced data analytics tools allows producers to analyze vast amounts of operational data, offering insights into process inefficiencies. According to a report by McKinsey & Company, companies implementing data-driven decision-making tactics can improve productivity by 5 to 6% annually. This shift towards automation and data-centric operations not only fosters a more responsive manufacturing environment but also helps in tailoring production processes to better meet consumer demand, driving sustainable growth and innovation within the CNC milling sector.

Related Posts

-

China Manufacturing Thrives Amidst US China Tariff Challenges with Best Cnc Milling Solutions

-

How to Identify Top Manufacturers for Best CNC Milling Solutions Globally

-

Navigating the Future: Essential Insights into Multi Axis CNC Milling Machine Procurement

-

Emerging Trends in Precision CNC Machining for Global Buyers in 2025 and Practical Strategies to Leverage Them

-

Unlocking Precision: The Future of Cnc Machine Multi Axis for Global Manufacturers

-

Exploring Cnc Cutting Trends for Global Buyers in 2025

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219