What is a Motorized Valve and How Does It Work?

A Motorized Valve is an essential component in many industrial and residential systems. It automates the flow of fluids, improving efficiency and control. These valves can regulate water, gas, or other materials with precision.

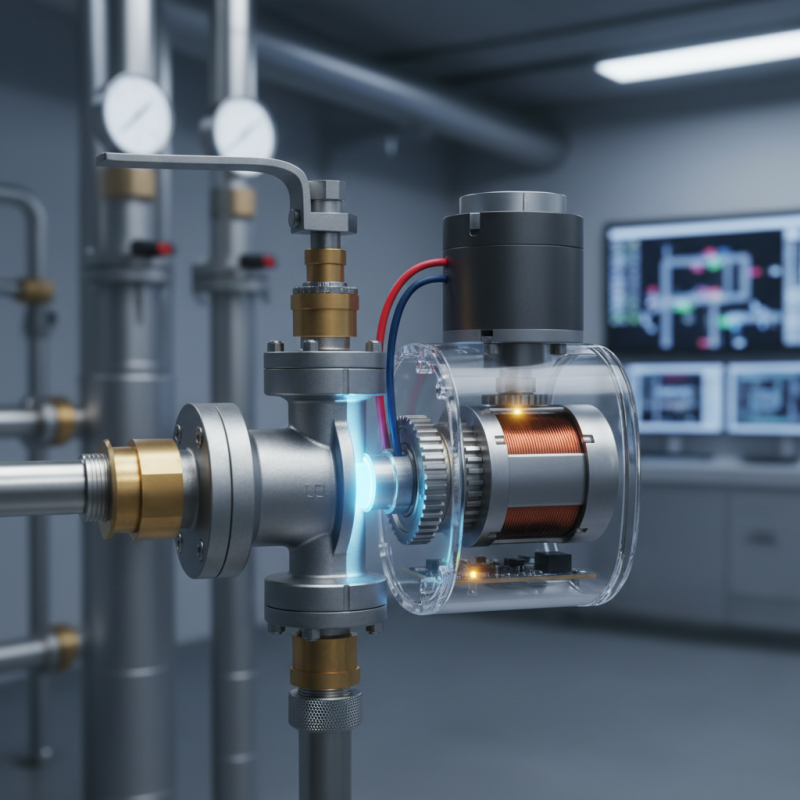

Understanding how a Motorized Valve works requires knowledge of its parts. It typically consists of a valve body and an actuator. The actuator opens or closes the valve using an electric motor. This mechanism allows for rapid response times, essential in emergency situations.

However, relying solely on technology has its flaws. For instance, electrical failures can lead to unforeseen issues. Regular maintenance is crucial to ensure proper function. Thus, awareness and understanding of the Motorized Valve's mechanism become vital in modern systems.

What is a Motorized Valve?

Motorized valves are automated devices used to control the flow of liquids or gases in various systems. They come equipped with electric or pneumatic actuators. These actuators open or close the valve based on control signals. According to market research, the global motorized valve market is projected to grow at a CAGR of 6.3% from 2021 to 2028. This increase highlights their importance in sectors like water treatment and HVAC.

In design, motorized valves can be remotely operated, enhancing convenience. For example, they can adjust flow rates based on system pressure and temperature changes. This capability reduces energy waste and improves efficiency. However, users must consider potential maintenance challenges. Regular wear in actuators can lead to failures. An inefficient valve may cause system imbalances, resulting in increased operational costs.

Moreover, selecting the right motorized valve is crucial. Sizing and type must align with system specifications. Poor choices can lead to inefficiencies. A report by the International Journal of Energy Management emphasizes that improper valve selection may decrease system performance by up to 30%. Attention to detail in these components is vital, as it directly influences overall system reliability and cost-effectiveness.

What is a Motorized Valve and How Does It Work?

| Dimension | Data |

|---|---|

| Type | Electric Motorized Valve |

| Operation | Automatically opens or closes valves based on electrical signals |

| Applications | HVAC, Water Management, Industrial Processes |

| Materials | Brass, Stainless Steel, PVC |

| Power Supply | AC or DC Voltage |

| Control Type | On/Off or Proportional Control |

| Size Range | 1/2 inch to 24 inches |

| Flow Rate | Varies based on valve size (up to several hundred GPM) |

Types of Motorized Valves and Their Applications

Motorized valves come in various types, each serving unique applications. Actuated ball valves are popular in industries like water treatment. They offer quick and reliable flow control. These valves open or close fully, making them energy-efficient.

In contrast, motorized butterfly valves are often used in HVAC systems. They regulate airflow and can be adjusted to different positions. Their design allows for a tight seal, preventing leaks. However, their installation can be tricky, as improper positioning affects performance.

Another type is the globe valve. This valve is often favored for throttling applications. It provides precise flow regulation but can be prone to wear over time. Users might find it challenging to maintain the right balance. Finding the right motorized valve requires consideration of specific needs. Compatibility is crucial for effective operation.

How Motorized Valves Operate Mechanically

Motorized valves play a crucial role in various industrial applications. Mechanically, they consist of a valve body, an actuator, and an electronic control system. These components work together to manage the flow of fluids in pipes. Typically, the actuator receives signals from the control system. It then opens or closes the valve based on the desired settings. It’s a straightforward mechanism, yet it requires precision.

Data from industry reports suggest that over 70% of process failures are due to valve malfunctions. Regular maintenance is essential for optimal performance. Some systems may experience delays in response time. This can lead to inefficiencies. Poorly calibrated actuators can result in unintended flow rates. Operators must be vigilant about these issues.

Additionally, the choice of actuator type can influence performance. Electric actuators are popular due to their automation capabilities. However, pneumatic options may offer faster response times. The challenge is balancing performance and cost. Accurate data is vital. However, many facilities lack up-to-date information on valve conditions. This gap needs addressing for better system reliability.

Advantages of Using Motorized Valves in Systems

Motorized valves are essential components in various systems. These devices automate the control of fluid flow. They replace manual valves, making management simpler and more efficient. By using motors, these valves can quickly open or close. This speed is crucial in urgent situations, like safety protocols in industrial setups.

One advantage of motorized valves is their precision. They can adjust flow rates accurately. This capability minimizes waste and optimizes system performance. In complex systems, precision can lead to significant energy savings. Another benefit is remote operation. Operators can control valves from a distance, enhancing safety and convenience. However, reliance on technology brings challenges. Power outages can disrupt operations. Regular maintenance is crucial to prevent unexpected failures.

In addition to precision, motorized valves offer flexibility. They can be integrated with automated systems and sensors. This integration allows for real-time monitoring. With better control, systems can respond to changing conditions dynamically. Yet, implementing these valves can be complex. Proper design and configuration are vital. Mistakes in setup can lead to inefficiencies and safety risks. This tension between automation and oversight remains a topic for reflection.

Maintenance and Troubleshooting for Motorized Valves

Motorized valves play a crucial role in controlling fluid flow in various systems. Regular maintenance is essential to ensure optimal performance. Start by checking the valve for any leaks or unusual noises. These issues can indicate wear or improper function. Cleaning the valve periodically helps prevent buildup that can hinder performance.

Troubleshooting motorized valves can sometimes be straightforward. If a valve fails to open or close, inspect the power supply. A simple disconnection or blown fuse could be the culprit. Additionally, ensure that the actuator is properly aligned with the valve. Misalignment often leads to operational problems. It’s important to address these issues quickly to avoid more significant failures.

Even with proper care, motorized valves can still show signs of wear. If the valve is resistant to movement, it might need lubrication. Remember that not every solution is perfect. Sometimes, replacing components may be necessary. Keep an eye on the system’s overall performance and don’t hesitate to seek professional help if things don’t improve.

Article Source:

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219