Unmatched Manufacturing Excellence: Discover the Best Screw Machines from China’s Leading Factory

In the highly competitive world of manufacturing, screw machines play a pivotal role in the production of precision components across various industries. According to a report by Market Research Future, the global screw machine market is projected to grow at a CAGR of 5.1% from 2021 to 2027, reaching a valuation of approximately $3 billion. This growth is driven by advancements in technology and increasing demand for efficient manufacturing processes. As companies strive for unmatched manufacturing excellence, selecting a high-quality screw machine manufacturer is crucial. With numerous options available, understanding how to choose the right manufacturer can set businesses apart in terms of cost-effectiveness, quality, and delivery times. This blog will explore key factors to consider when selecting a top-tier screw machine manufacturer from China's leading factories, equipping you with the insights needed to make informed decisions in a rapidly evolving market.

Understanding Screw Machines: Key Features and Benefits Explained

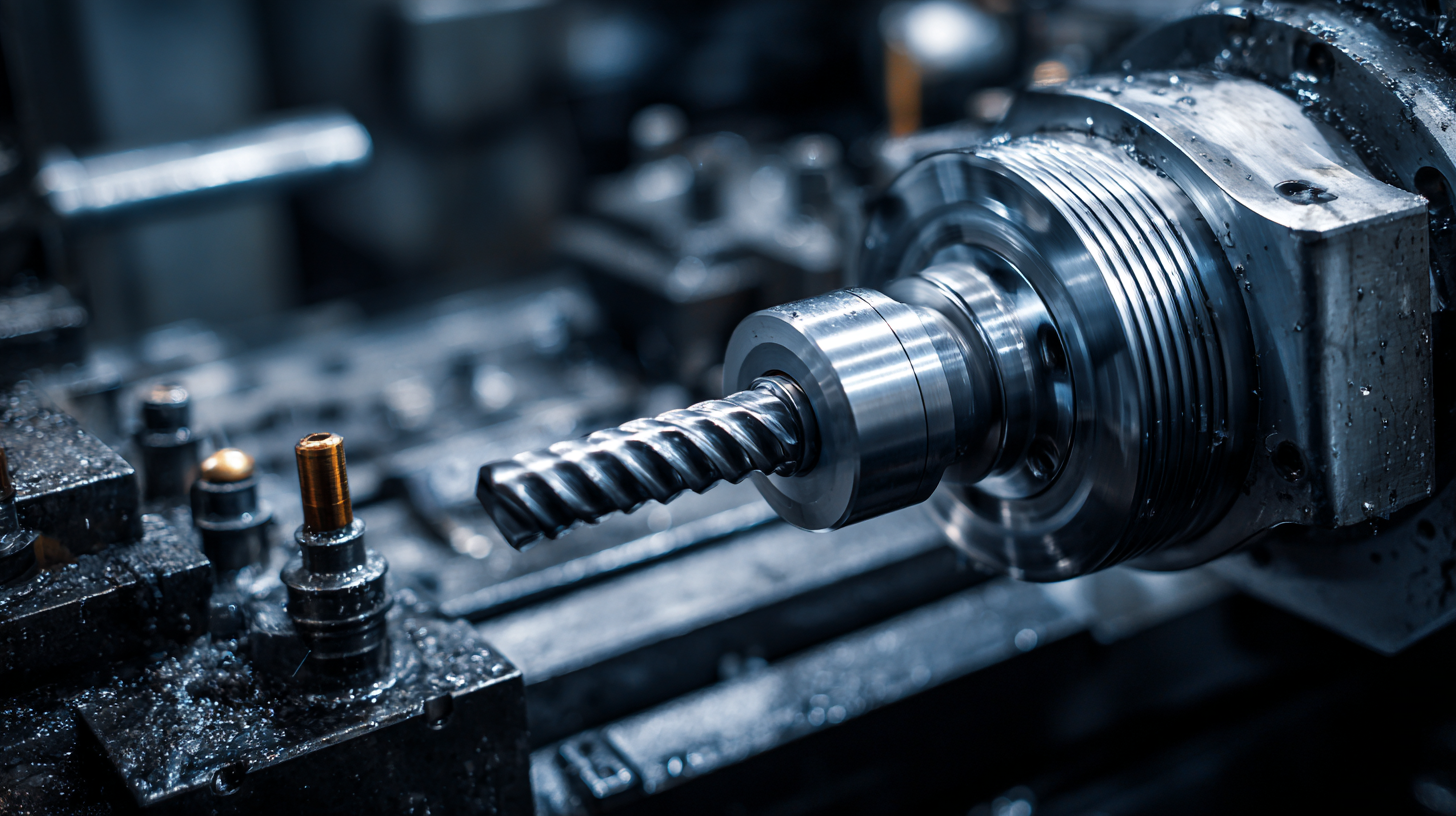

Screw machines are indispensable tools in the manufacturing sector, primarily known for their efficiency and precision in producing intricate components. These machines utilize a rotating spindle to shape raw materials into the desired forms, making them ideal for high-volume production. A key feature of screw machines is their ability to perform multiple operations in a single setup, significantly reducing the time and cost involved in the manufacturing process. This integration of tasks leads to higher productivity outputs, which is crucial for industries seeking to maintain a competitive edge.

One of the standout benefits of screw machines is their versatility. They can be customized to create a wide variety of products, from complex mechanical parts to simple fasteners. This adaptability means that manufacturers can switch between projects with ease, ensuring minimal downtime. Moreover, advanced technologies embedded within modern screw machines enhance precision, leading to superior product quality and consistency. This combination of efficiency, adaptability, and high-quality output underscores why screw machines from China’s leading factories are regarded as exemplary in the industry.

How to Choose the Right Screw Machine for Your Manufacturing Needs

When selecting the right screw machine for your manufacturing needs, understanding the specific requirements of your production process is crucial. According to a report by Technavio, the global CNC machine market is expected to grow by over USD 15 billion between 2020 and 2024, showcasing the rising demand for precision and efficiency in production. Manufacturers should assess the features such as automatic vs. manual operations, machine size, and speed capacity, as these factors greatly influence the quality and cost-effectiveness of the final products.

Additionally, evaluating the production volume and material compatibility is essential. A study from Research and Markets reveals that the demand for screw machines is increasingly driven by the automotive and aerospace sectors, which require high versatility and durability from these machines. Investing in a machine that can handle various materials, from metals to composites, ensures that your manufacturing process remains flexible and future-proof. Therefore, consider suppliers with a proven track record in delivering quality screw machines tailored to your operational needs, such as those from China's leading factories that are renowned for their technological advancements and efficient production capabilities.

The Manufacturing Process: How China’s Leading Factories Produce Screw Machines

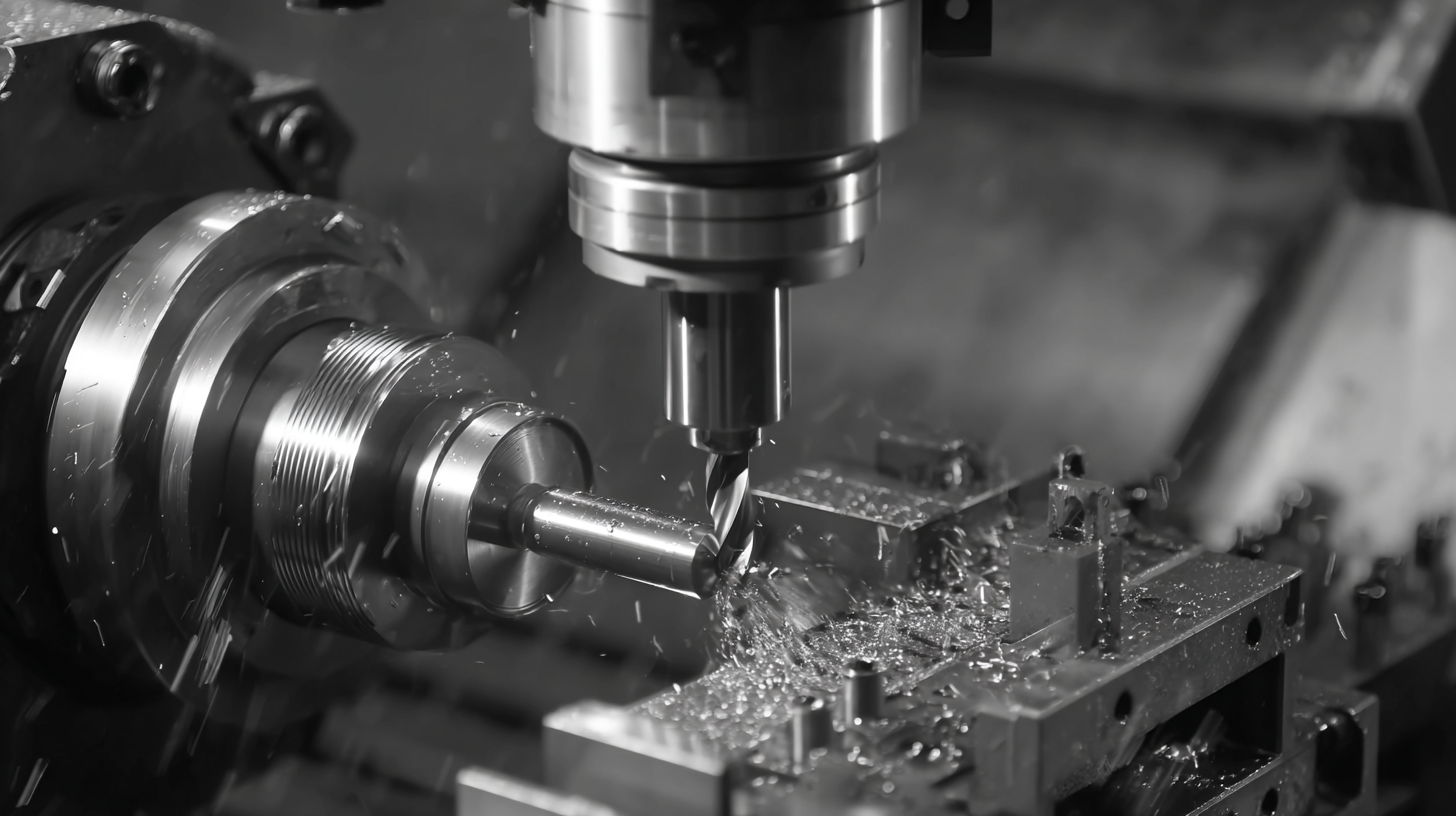

China's leading factories have redefined the manufacturing process for screw machines, leveraging advanced technology and efficient production methodologies. According to recent market analysis, the linear motion products sector, which encompasses screw machines, continues to experience significant growth, with the extrusion machinery market projected to reach approximately USD 11.58 billion by 2030 at a CAGR of 4.5%. This growth is driven by increasing applications in automotive, construction, and robotics, where precision and reliability are paramount.

The manufacturing process in these factories emphasizes automation and innovation. For instance, the integration of advanced extrusion techniques allows manufacturers to produce high-quality, customized screw components rapidly. The emergence of specialized products like planetary roller screws highlights the industry's focus on meeting the demands of next-gen robotics, which require advanced and costly components for enhanced performance. As China's manufacturing capabilities evolve, these factories are positioning themselves at the forefront of the global market, setting new standards for excellence in screw machine production.

Manufacturing Excellence: Production Efficiency of Screw Machines

Quality Control: Ensuring Excellence in Screw Machine Production

In the competitive landscape of screw manufacturing,

quality control has

never been more crucial. The recent implementation of

mandatory quality standards

by the government aims to reduce the influx of sub-standard screws, thereby raising

the benchmarks for manufacturers. This regulation is particularly essential as the

demand for screw components continues to escalate, with industries like

orthopedics seeing a marked increase.

For instance, companies faced with high production demand have turned to advanced

metrology solutions, as precise measurements are integral to maintaining

product quality. By utilizing

optical measuring technologies, companies are able to enhance their

production processes, ensuring that they meet stringent safety and performance

requirements.

Moreover, innovative manufacturing practices are redefining quality assurance protocols.

The introduction of smart factories equipped with real-time digital twins and

advanced automation plays a pivotal role in monitoring production quality. Such facilities

not only streamline operations but also bolster the reliability of the final products.

Furthermore, recent advancements in extrusion technology have simplified processes, leading

to enhancements in product quality and consistency. As the manufacturing landscape evolves,

the commitment to quality control will undoubtedly

serve as the foundation for sustained excellence in screw machine production.

Innovations in Screw Machine Technology from China’s Top Manufacturers

In recent years, China's screw machine industry has undergone a significant transformation driven by technological advancements and innovative manufacturing processes. According to a report from MarketsandMarkets, the global CNC machine market, which includes screw machines, is projected to reach $100 billion by 2025, with a compound annual growth rate (CAGR) of 6.3%. A substantial portion of this growth is attributed to the robust performance of Chinese manufacturers, who are continuously enhancing their product offerings through cutting-edge technology and automation.

Leading Chinese factories are now integrating smart manufacturing practices and Industry 4.0 technologies into their production lines. These innovations not only improve the efficiency and precision of screw machines but also contribute to sustainable manufacturing processes. For instance, a study by Deloitte indicates that by adopting advanced technologies like IoT and AI, Chinese manufacturers can increase production efficiency by up to 20%. This shift not only positions these factories at the forefront of screw machine production but also equips them to meet the diverse demands of global markets with agility and precision.

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219