Top Five Industries Transforming Production with Best CNC Turning Parts

In recent years, the manufacturing landscape has undergone a significant transformation driven by technological advancements, particularly within the realm of CNC turning parts. According to a recent report by Grand View Research, the global CNC machining market is expected to reach $100.79 billion by 2025, growing at a CAGR of 8.3%. This surge is largely attributed to the increasing demand for precision-engineered components in various industries such as aerospace, automotive, and medical devices.

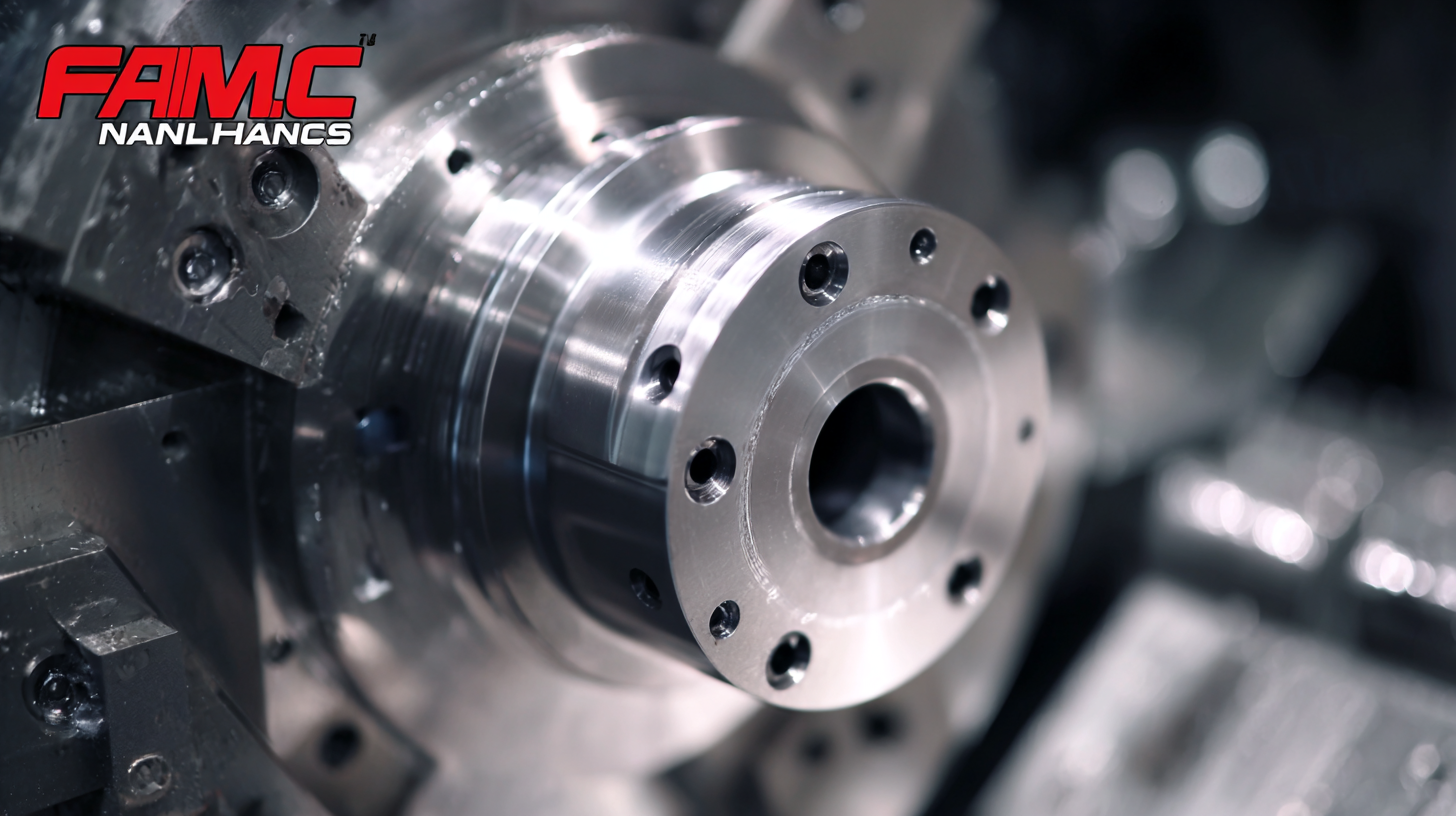

CNC turning parts, known for their ability to produce complex geometries with high accuracy and repeatability, play a pivotal role in this evolution. As industries strive to enhance productivity and reduce operational costs, embracing innovative machinery and techniques like CNC turning is vital for maintaining competitiveness, ultimately redefining production processes across multiple sectors.

The Role of CNC Turning Parts in Revolutionizing Manufacturing Industries

The evolution of manufacturing industries in recent years has been significantly influenced by the integration of CNC turning parts. These precision-engineered components enable manufacturers to achieve unmatched accuracy and efficiency in production processes. By automating the turning of materials, CNC machines minimize human error and reduce lead times, facilitating quicker response to market demands. This shift leads to enhanced product quality, allowing companies to maintain competitive advantage in a crowded marketplace.

Industries such as automotive, aerospace, and medical devices have particularly benefited from the high precision that CNC turning parts offer. In the automotive sector, for instance, complex geometries needed for engine components can be produced with ease, resulting in higher performance and reliability. Similarly, the aerospace sector relies on CNC turning for lightweight yet durable parts, which are critical for safety and performance. The seamless integration of these advanced technologies not only transforms production capabilities but also paves the way for innovation and design versatility, reflecting a new era of manufacturing excellence.

Top Five Industries Transforming Production with Best CNC Turning Parts

CNC turning parts are revolutionizing the manufacturing industries by enhancing efficiency and precision. This chart illustrates the impact of CNC turning parts on productivity across the top five industries.

Key Innovations in CNC Technology Driving Production Efficiency

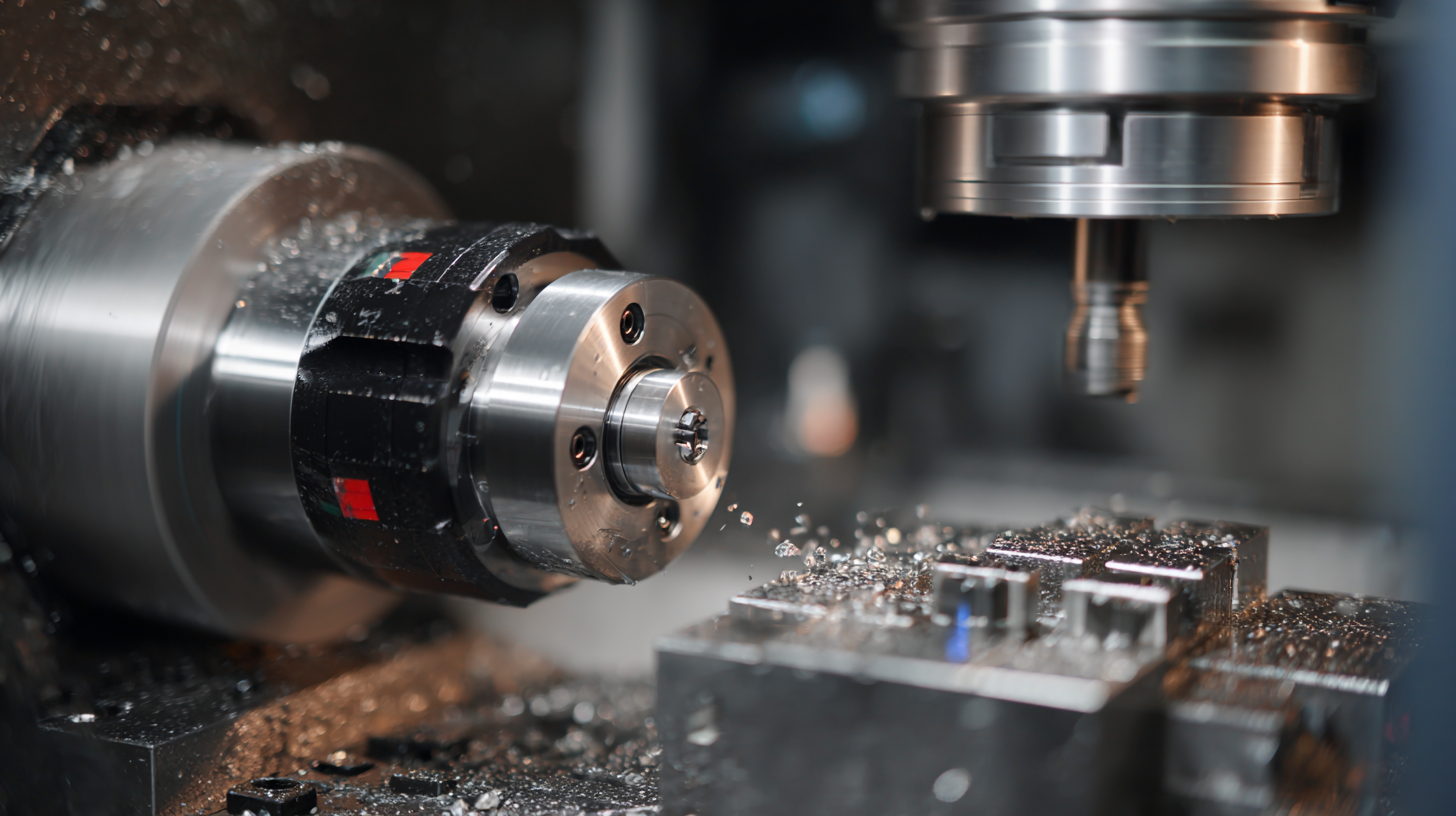

In today's manufacturing landscape, CNC technology is at the forefront of driving production efficiency. The evolution of CNC turning parts has sparked numerous innovations that streamline operations, reduce waste, and enhance precision. One significant advancement is the integration of automation and robotics, which allows for faster production cycles and minimizes human error. By automating the loading and unloading of parts, manufacturers can significantly increase throughput, ensuring that machines operate at optimal levels without long downtimes.

Another key innovation is the adoption of advanced materials and cutting tools. With the development of high-performance alloys and coated inserts, CNC turning processes can achieve finer tolerances and improved surface finishes. This not only enhances the quality of the final product but also extends the life span of the tools, reducing the frequency of replacements and maintenance. Moreover, the implementation of real-time monitoring and data analytics in CNC machines enables manufacturers to gather critical insights into their production processes, facilitating proactive adjustments that enhance efficiency and output. As these technological advancements continue to unfold, industries are poised to achieve unprecedented levels of productivity and innovation in CNC machining.

Top Industries Benefiting from Advanced CNC Turning Solutions

The advent of advanced CNC turning solutions is revolutionizing various industries, enabling them to enhance production efficiency and precision. The automotive sector is one of the top beneficiaries, utilizing CNC turning to manufacture intricate components such as gears, shafts, and brackets. These parts require extreme accuracy and consistency, and CNC machines excel in delivering high-quality outputs that meet stringent industry standards, ultimately leading to improved vehicle performance and reduced manufacturing times.

Another industry reaping the rewards of CNC turning technology is aerospace. With safety and reliability paramount, aerospace manufacturers depend on advanced CNC turning to create lightweight yet durable components. From turbine blades to structural fuselage parts, the precision and repeatability offered by CNC machining are critical. This not only aids in meeting regulatory requirements but also facilitates the innovation of more efficient aircraft designs.

Additionally, the medical device industry is harnessing CNC turning for producing precision-engineered parts for surgical instruments and implants. With the growing demand for complex geometries and biocompatible materials, CNC turning technology enables manufacturers to produce parts that are both functional and compliant with medical regulations. This advancement not only improves patient outcomes but also streamlines production processes, allowing for faster delivery of essential medical products.

Market Trends Shaping the Future of CNC Production by 2025

The landscape of CNC production is rapidly evolving, influenced by several key market trends that are expected to shape the industry by 2025. One significant trend is the rise of automation technologies. With advancements in robotics and AI, manufacturers are increasingly integrating automated processes into their CNC operations. This shift not only enhances efficiency but also reduces human error, leading to higher precision in CNC turned parts. As competition intensifies, companies that embrace automation will gain a substantial edge in production speed and cost-effectiveness.

Another trend is the growing demand for customized and complex designs. As industries like aerospace, automotive, and healthcare continue to innovate, the need for bespoke CNC turning parts that meet specific requirements is on the rise. This demand is pushing manufacturers to adopt flexible manufacturing systems that can quickly adapt to varying design specifications. Additionally, sustainability is becoming a focal point, with more companies seeking to implement eco-friendly practices in their production processes. This includes using sustainable materials and minimizing waste, which is not only beneficial for the environment but also appeals to a more environmentally-conscious consumer base.

Top Five Industries Transforming Production with Best CNC Turning Parts - Market Trends Shaping the Future of CNC Production by 2025

| Industry | Growth Rate (%) | Market Size (Billion $) | Key Applications | CNC Parts Utilized |

|---|---|---|---|---|

| Aerospace | 8.5 | 36.2 | Engine Components, Structural Parts | Shafts, Housings |

| Automotive | 7.2 | 104.8 | Engine Parts, Transmission Units | Brackets, Couplings |

| Medical Devices | 9.1 | 45.5 | Surgical Instruments, Implants | Precision Enclosures, Connectors |

| Electronics | 6.8 | 58.3 | Circuit Boards, Casings | Mounting Brackets, Enclosures |

| Defense | 8.0 | 29.4 | Weapon Systems, Equipment | Structural Components, Mounts |

Analyzing the Competitive Landscape for CNC Turning Parts Manufacturers

The competitive landscape for CNC turning parts manufacturers is evolving rapidly, driven by advancements in technology and changing market demands. Key players in the industry are leveraging AI and automation to improve production efficiency and enhance precision, which are critical factors in distinguishing themselves from competitors. The CNC machine tools market is projected to grow significantly, with an expected increase of USD 21.9 billion by 2029. This growth is fueled by the rising need for high-precision and multi-axis machining centers, as manufacturers strive to meet the intricate requirements of modern production processes.

Tips for manufacturers looking to thrive in this competitive environment include investing in AI-driven technologies that can optimize machining operations, enabling faster turnaround times and reduced waste. Additionally, staying updated on market trends and customer demands is crucial for adapting product offerings to meet evolving requirements. Collaborating with technology partners can also foster innovation and accelerate the development of cutting-edge CNC turning parts, solidifying a manufacturer’s position in the market.

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219