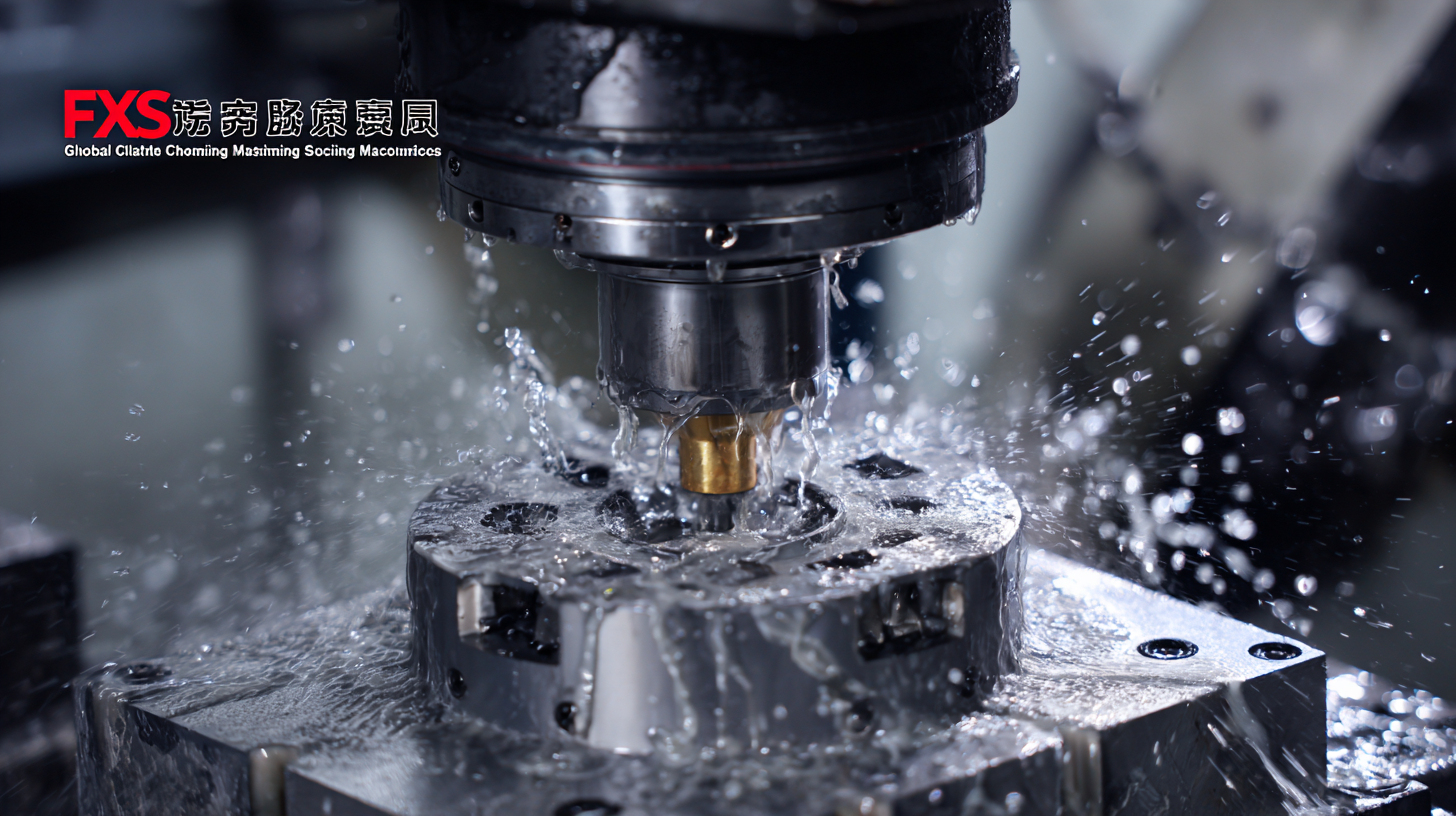

Global Trust in Quality Chinese Manufacturing for Best Multi Axis Machining Solutions

In an era where precision and efficiency are paramount, the manufacturing industry has increasingly turned its focus towards advanced technologies to meet the growing demand for high-quality products. Among these technologies, Multi Axis Machining stands out as a cutting-edge solution that enhances manufacturing capabilities and expands the horizons of design complexity. As global trust in Chinese manufacturing rises, it becomes essential to explore how this expertise translates into the delivery of the best Multi Axis Machining solutions. This blog will delve into the unique benefits and tips surrounding Multi Axis Machining, showcasing how it not only elevates production standards but also reinforces quality assurance in a competitive landscape. Join us as we uncover the vital role that Chinese manufacturers play in revolutionizing the way we approach intricate machining processes, ensuring that quality remains a top priority in a rapidly evolving market.

The Rise of Chinese Manufacturing: A Global Perspective on Quality

The rise of Chinese manufacturing has been nothing short of transformative on the global stage, particularly in sectors like precision engineering and multi-axis machining. Over the past few decades, China has evolved from being merely the world's factory to becoming a leader in high-quality manufacturing solutions. This shift has been driven by significant investments in technology, skilled labor, and innovation, allowing Chinese manufacturers to produce complex components that meet international standards.

Consequently, companies worldwide are increasingly turning to Chinese manufacturers for their multi-axis machining needs. The emphasis on quality control, adherence to international protocols, and the use of advanced manufacturing techniques have resulted in components that not only fulfill functional requirements but also enhance overall product performance. As globalization continues to expand, Chinese manufacturing stands as a testament to how dedication to quality can foster international trust and collaboration, positioning China at the forefront of the global manufacturing arena.

Key Industry Standards Driving Multi Axis Machining Excellence

In the competitive landscape of manufacturing, quality standards are paramount for achieving excellence in multi-axis machining. Key industry standards, such as ISO 9001 and AS9100, play a crucial role in ensuring that manufacturers maintain strict quality control throughout their processes. These standards not only enhance product reliability but also boost customer confidence in Chinese manufacturing capabilities. By adhering to these benchmarks, companies can offer innovative and precise solutions tailored to meet diverse industrial needs.

Tip: It is essential for manufacturers to regularly undergo audits and certifications to stay compliant with these quality standards, as this can significantly elevate their reputation in the global market.

Moreover, industry standardization promotes best practices that streamline production workflows and enhance efficiency. For instance, implementing lean manufacturing techniques can reduce waste and optimize resource utilization. Multi-axis machining, known for its ability to produce intricate parts in a single setup, benefits extensively from these methodologies, resulting in reduced lead times and improved overall productivity.

Tip: Regular training for staff on the latest machining technologies and industry standards is vital, as a well-informed workforce is key to achieving consistent quality and innovation in production.

Global Trust in Quality Chinese Manufacturing for Best Multi Axis Machining Solutions - Key Industry Standards Driving Multi Axis Machining Excellence

| Dimension | Value |

|---|---|

| Average Precision (μm) | 5 |

| Production Capacity (units/month) | 2000 |

| ISO Certification Rate (%) | 98 |

| Average Lead Time (days) | 15 |

| Customer Satisfaction Rate (%) | 92 |

| Training Hours per Employee (hours/year) | 40 |

| Percentage of Automated Processes (%) | 75 |

Digital Transformation in Manufacturing: Enhancing Precision and Efficiency

In today's fast-paced manufacturing landscape, digital transformation is not just a trend but a necessity for enhancing precision and efficiency. By integrating advanced technologies such as artificial intelligence, the Internet of Things (IoT), and big data analytics, manufacturers can streamline operations, reduce waste, and improve product quality. These innovations enable real-time monitoring and data collection, allowing companies to make informed decisions that lead to enhanced operational performance and lower costs in the long run.

Moreover, the shift towards digital methods empowers manufacturers to adopt agile practices, responding swiftly to market demands and customer preferences. For instance, multi-axis machining solutions, known for their versatility and precision, benefit greatly from digital tools. Upgrading traditional processes with digital technologies allows for more complex geometries and tighter tolerances, ensuring that products meet the high standards expected globally. As more manufacturers in China embrace this digital transformation, the reputation for high-quality machinery and skilled craftsmanship continues to solidify, showcasing an impressive commitment to excellence in the global market.

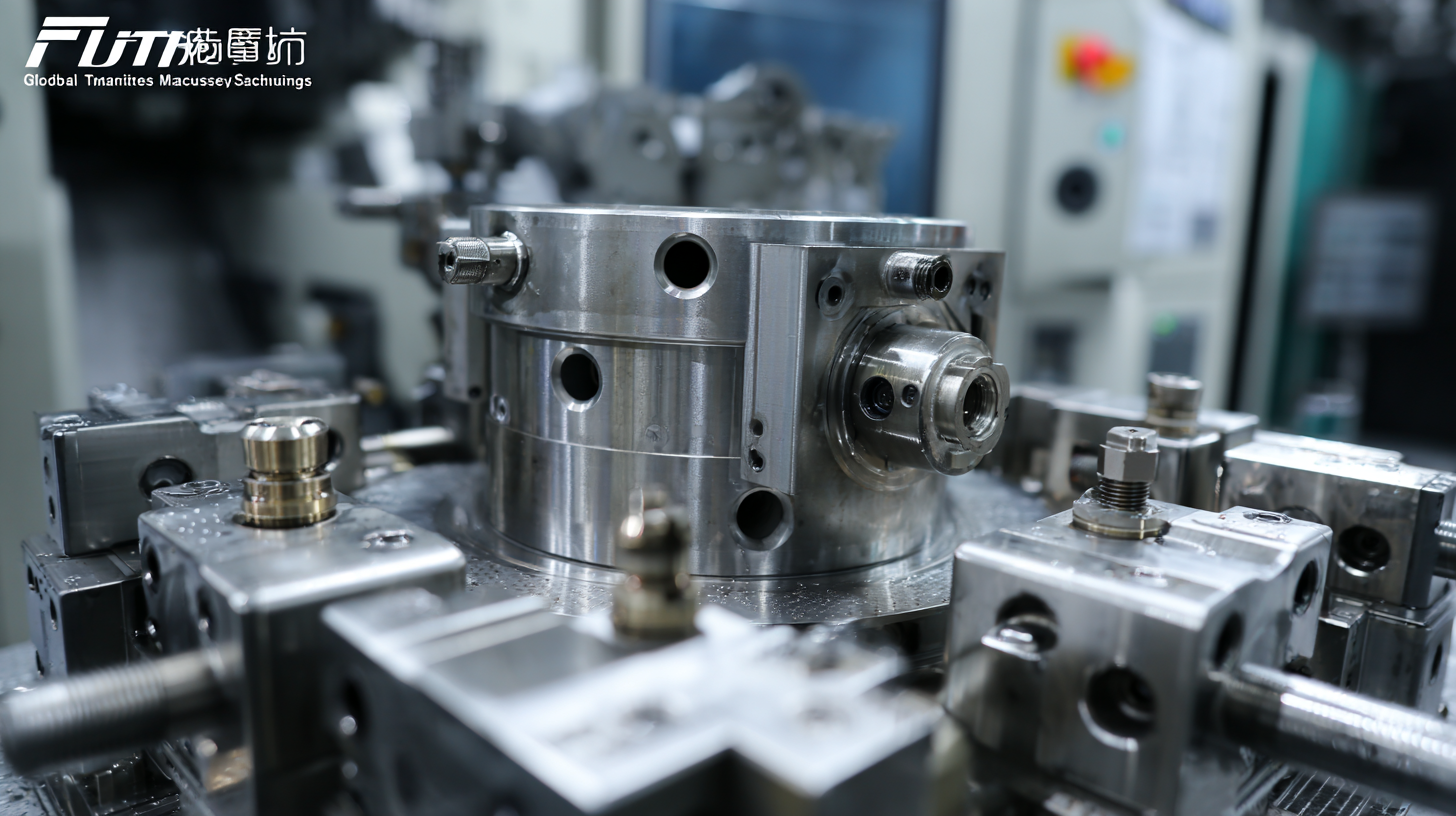

Reasons Behind the Trust in Chinese Multi Axis Machining Solutions

In recent years, global industries have increasingly turned to Chinese manufacturers for multi-axis machining solutions, a trend underpinned by a blend of efficiency, cost-effectiveness, and innovation. One of the key reasons for this trust lies in China's robust manufacturing infrastructure, which has continually evolved to meet the demands of international markets. Chinese manufacturers leverage advanced technologies and rigorous quality control measures, ensuring that their products not only meet but often exceed global standards. This commitment to quality has fostered substantial confidence among international clients.

Moreover, the long-standing experience of Chinese manufacturers in multi-axis machining contributes to their reputation for reliability. The country's deep pool of skilled labor, combined with ongoing investments in research and development, positions these manufacturers at the forefront of machining technology. As industries worldwide seek precision and versatility in machining operations, China has emerged as a go-to destination, providing tailored solutions that address specific client needs. This versatility, coupled with competitive pricing, makes Chinese multi-axis machining solutions a preferred choice for businesses aiming to enhance their operational efficiency and product quality.

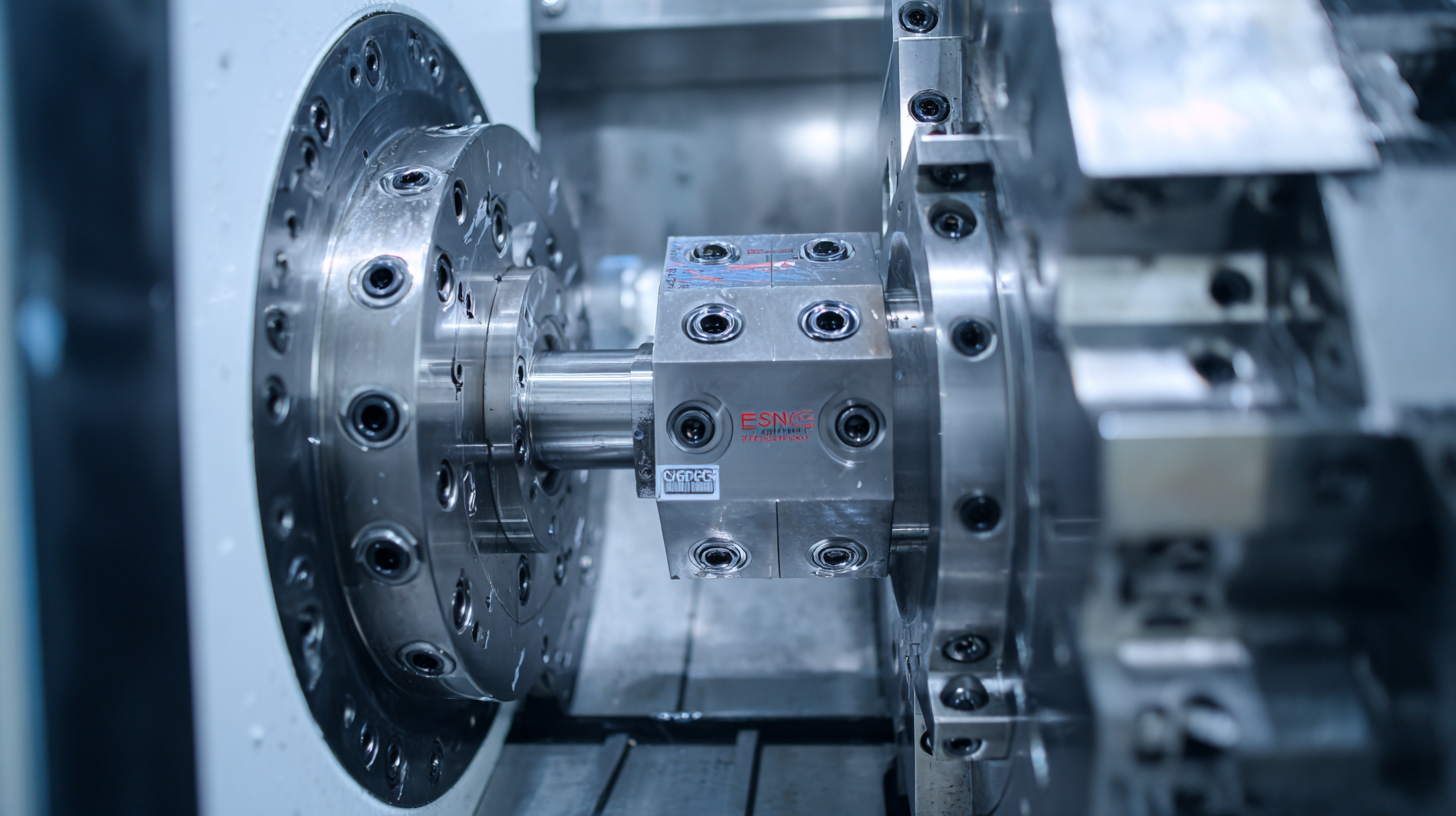

The Future of Multi Axis Machining: Innovations and Global Impact

The future of multi-axis machining is poised for remarkable innovations that will not only enhance manufacturing efficiency but also have a significant global impact. As industries increasingly demand precision and versatility, advancements in technology are paving the way for more sophisticated multi-axis machines that can handle complex geometries with ease. This evolution is crucial, as it allows manufacturers to produce high-quality components faster, reducing lead times and costs.

Tip: When selecting a multi-axis machining solution, consider the machine's capability to integrate with advanced software systems. Smart technology can optimize the machining process through real-time monitoring and adjustments, ensuring that the highest standards of quality are maintained.

Moreover, the global impact of these innovations is substantial. Countries that invest in cutting-edge multi-axis machining technology will strengthen their manufacturing sectors, positioning themselves as leaders in the competitive global market. The ripple effect of these advancements will also enhance job creation and economic growth, as skilled labor is needed to operate and maintain these sophisticated machines.

Tip: Stay updated on industry trends by attending trade shows and workshops, as this will provide insights into the latest technologies and methodologies in multi-axis machining. Networking with experts in the field can also open doors to new opportunities and collaborations.

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219