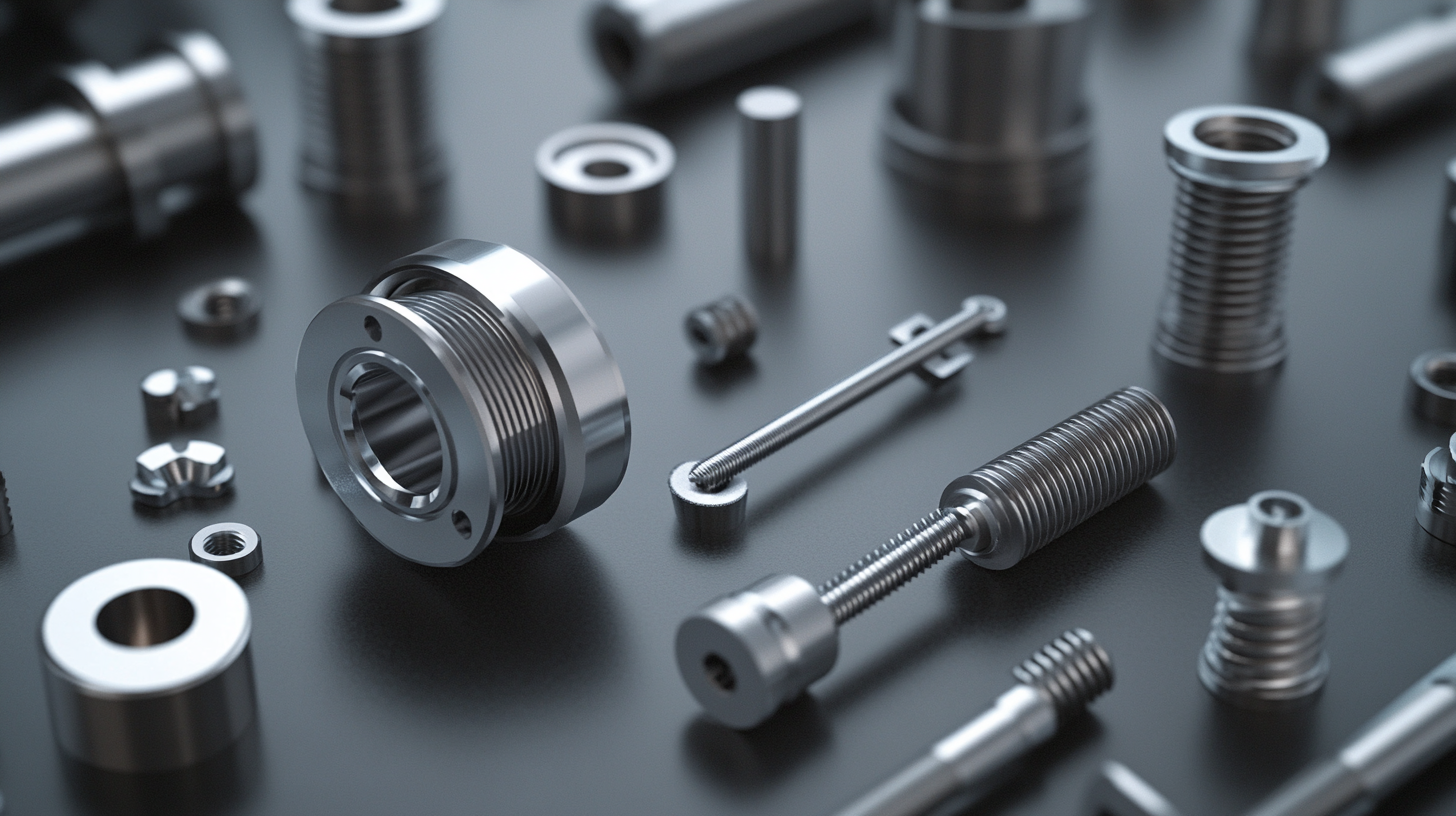

7 Insider Secrets for Sourcing High Quality Cnc Turning Parts Globally

High-quality CNC turning parts sourcing for businesses, which crave efficiency and quality, is one major factor in these days` manufacturing scenario. According to a report by the International Federation of Robotics, the market for CNC machined components is expected to grow globally at a CAGR of 7.5% for the next five years. Therefore, it is absolutely imperative for manufacturers to follow and adopt the best practices for sourcing so as to compete in a plethora of competitive markets.

Some well-informed considerations about global sourcing will navigate its various complexities, especially in assessing a supplier's capability and product quality. A note by Market Research Future indicates that more than 60% of manufacturers have faced various challenges with CNC turning part quality, which may greatly impact the performance of the final product and hence customer satisfaction. Therefore the sourcing of high-quality CNC turning parts is a matter to be understood in detail if companies want to claim innovation and success in the market, coupled with sustainable growth.

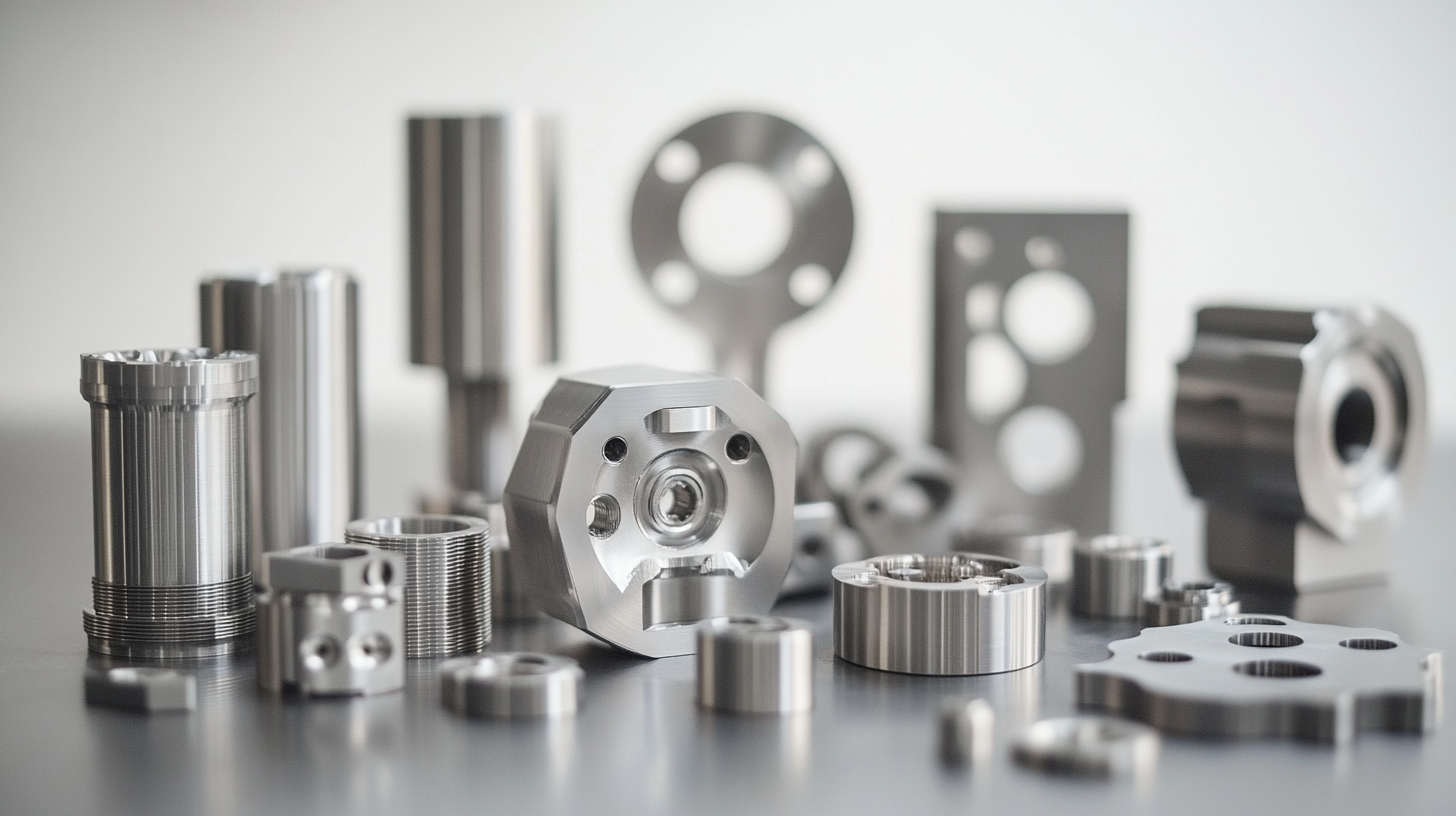

Understanding the Importance of Quality Assurance in CNC Turning Parts

It is extremely important to maintain quality assurance while outsourcing CNC turning parts, as below-average components will create large leeway in operation and cost. A report put out by Deloitte states that those companies that have a hard focus on quality assurance in production can bring their production costs down by as much as 30%. Therefore, it becomes imperative that buyers focus not only on pricing but also assess the quality processes of the suppliers. The global CNC machining market is expected to be valued at USD100 billion by the year 2025, and this creates demand for high-quality products across industries like aerospace, automotive, and electronics. In an era of cutthroat competition, it is of utmost importance that CNC turning parts conform to stringent quality standards that may well ensure a competitive advantage. Employing quality assurance systems like ISO9001 certification and Six Sigma methodologies could greatly improve product reliability and customer satisfaction. Quality assurance is more than adherence to standards; it means monitoring and continuous improvement of manufacturing processes. According to a study published in the Journal of Manufacturing Science and Engineering, organizations conducting proactive quality audits reduce product defects by 25 percent; thus, successful quality control becomes a very important parameter in sustainable sourcing, keeping manufacturers away from plague recalls while enhancing global market credibility.

Identifying Reliable Global Suppliers for CNC Turning Components

In sourcing high-quality CNC-turned parts, finding trustworthy suppliers on the global market is essential for product quality and achieving business success. The first operational step in sourcing CNC-turned components is research. Online platforms, industry directories, and trade shows serve as excellent means to generate a list of potential suppliers. Evaluate a prospective supplier's past performance by reviewing client testimonials and case studies. These can shed light on the vendor's capability and reliability.

Before deciding on suppliers, certify those that match quality requirements and manufacturing standards. Pursue suppliers that have certification from ISO 9001; it shows that the supplier is committed to quality management and operational excellence. The manner in which the supplier interacts directly with you is also an avenue to evaluate the supplier's responsiveness and customer service, which are critical elements of a long-term relationship.

The other most important factor regarding supplier assessment is technology. Investigate whether the suppliers own or operate CNC machines that are advanced by present-day standards. This relates directly to the quality of goods produced. Sample parts should also be requested prior to commitment, lending first-hand insight into quality standards. This and other measures will make sure that partnerships with suppliers are secured that will not only solve short-term problems but will be in alignment with long-term strategies of product quality and innovation.

Evaluating Material Specifications for Superior CNC Turning Parts

Evaluation of material specifications is extremely important in sourcing the CNC turning parts of superior quality from around the world in modern-day manufacturing. These days, industries require very light and strong components, and advanced materials, such as titanium alloy, are emerging as the materials of choice because of their extraordinary strength-to-weight ratio and corrosion resistance. These two characteristics not only enhance the performance of the components but also improve the overall efficiency of mechanical systems.

The acceptance of additive manufacturing (AM) technologies today adds yet another dimension to sourcing. AM offers designs that are difficult to achieve by conventional machining processes. By using composite materials and novel production methods, manufacturers can create parts that are not only tough but also tailored to specific applications. This versatility in design and materials gives companies a competitive edge, particularly in industries like aerospace and automotive where precision and performance are the star players.

Meanwhile, AI is exploding in CNC machining process optimization, ensuring that the selected materials fulfill the required specifications. AI-based insights analyze the data from production lines to maximize material efficiency, minimize waste, and make production on-time. With the changing face of manufacturing, the look-out for superior material specifications and complementary capabilities of CNC turning and additive manufacturing will be key to producing superior-quality products.

Leveraging Technology for Efficient CNC Parts Sourcing

Fast sourcing of high-quality CNC turning parts in today's global market has come to be critical for manufacturers to keep up their competitive edges. The technology indeed plays a vital role in optimizing the sourcing process for CNC parts. An indication of how far-reaching this trend has become is the report of Grand View Research in 2022 that reveals the global CNC machine market is projected to reach USD 100 billion by 2025; this shows advanced technologies guaranteeing precision and efficiency in production.

Utilizing digitalization through online marketplaces and software solutions can immensely improve sourcing strategies. About 70% of manufacturers surveyed by IndustryWeek stated that sourcing time could be cut by 30% or higher due to the application of technologies. Fast design creation and revision are now possible with CAD and CNC simulation programs, greatly streamlining production and minimizing errors. Added to that, the infusion of AI into supply chain management now gives capacity for predictive analytics which gives the companies tools to anticipate changes in demand and adjust sourcing strategies accordingly.

Even the 3D printing machine alongside CNC machining proves to be an excellent advantage in prototyping and small batch production. AMFG says that using additive manufacturing around traditional machining processes can minimize lead time by as much as 50%. This can fast-track the development of products, as well as ensure that manufacturers regularly source quality CNC parts that meet their specifications to work through challenges associated with varying quality standards in global supply chains.

Navigating Cultural Differences in International CNC ManufacturingRelationships

This is very important to ensure that different cultures are managed well, especially in global CNC machining relationships where high-quality CNC turning parts are sourced internationally. Today, culture is a major issue in the ever-more-connected world, which makes differences impact communication and teamwork for manufacturing partners. A recent survey by the World Economic Forum showed that by just adopting good cross-cultural communications, business productivity could grow by even as high as 25%.

One such issue that has become quite commonplace is what is known as the 'cultural discount'. That is when cultural differences are underestimated by the companies, thereby misaligning expectations with that of reality, for example, McKinsey's study. The outcome is that that 35% more of those competing with diverse teams would perform better. Here we see how it comes, different points of views which lead to innovation and problem-solving in manufacturing types of processes. Hence, the manufacturers need to invest in cross-cultural training, which enables their teams to be equipped with necessary skills to tackle these complexities.

Moreover, globalization has become a bane for nations, with politics and economy referred as the secure knots that are tightly knotted across the world. Flexible absorption of distinct cultural customs expedites the negotiation procedure and makes long-term relations feasible. In terms of CNC turning parts, this refers to the comprehension of different quality standards, times to produce, and ways to communicate through specific regions, which interactively go into the structures of more resistive supply chains.

In companies converting into this different global manufacturing environment, it becomes increasingly important to promote cross-cultural ability. Companies can then use these discoveries not just for better sourcing strategies, but also to be able to position themselves as trailblazers in CNC manufacturing.

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219