Exploring the Future of Milling Machining: Innovations Transforming the Manufacturing Landscape

Milling machining has long been a cornerstone of manufacturing, shaping the way parts and components are produced across various industries. As we stand on the brink of a technological revolution, innovations in milling machining are set to transform the manufacturing landscape dramatically. With advancements in automation, artificial intelligence, and advanced materials, milling processes are becoming more efficient, precise, and adaptable. This exploration delves into the cutting-edge developments that are redefining conventional milling techniques, highlighting how these innovations are not only improving production capabilities but also paving the way for sustainable manufacturing practices. By examining the emerging trends in milling machining, we gain insight into a future where manufacturing is not just about creating products, but also about embracing smart technologies that enhance overall productivity and resource efficiency.

Understanding the Basics of Milling Machining and Its Applications

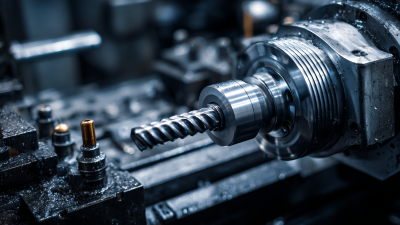

Milling machining is a versatile and fundamental manufacturing process that utilizes rotating cutting tools to remove material from a workpiece. This technique is predominantly used in the production of complex shapes, precise components, and intricate details across various industries. The basic principle involves a workpiece being held stationary while a multi-toothed cutter, which can be either vertical or horizontal, moves along multiple axes to achieve the desired contours and dimensions.

The applications of milling machining are extensive, ranging from the aerospace and automotive sectors to the medical and electronics fields. In aerospace, for example, milling is essential for creating lightweight, high-strength components with exact tolerances. In the medical field, it enables the production of intricate instruments and devices that are critical for patient care. With advancements in technology, including the integration of computer numerical control (CNC), milling processes have become even more efficient and precise, allowing manufacturers to explore new possibilities and innovate within their production lines.

Innovations in Milling Machining: Growth by Application

Key Innovations Revolutionizing Milling Technologies

The future of milling machining is being reshaped by a host of innovative technologies that enhance efficiency and precision in the manufacturing process. One of the foremost innovations is the advent of computer numerical control (CNC) systems, which allow for automated and highly accurate machining operations.

CNC technology enables faster production times while ensuring consistent quality, making it a staple in modern manufacturing facilities.

Additionally, the integration of advanced materials and coatings significantly improves tool performance and lifespan. For instance, the use of ceramic and carbide materials enhances wear resistance and reduces friction, allowing for higher cutting speeds and improved surface finishes. Moreover, developments in additive manufacturing processes expand the possibilities for creating complex geometries, further enhancing the capability of milling technologies.

As these innovations continue to evolve, they promise to drive the future of milling machining toward greater productivity and sustainability.

Integrating Smart Automation in Milling Processes

The integration of smart automation into milling processes is revolutionizing the manufacturing landscape, enhancing both efficiency and precision. By employing advanced technologies such as artificial intelligence and machine learning, manufacturers can now optimize machining parameters in real-time, leading to significant reductions in production times and material waste. Automated systems can analyze vast amounts of data to predict tool wear and machine faults, enabling preemptive maintenance and minimizing downtime.

Moreover, smart automation facilitates a higher level of customization in milling operations. With the ability to integrate Internet of Things (IoT) devices, manufacturers can achieve seamless communication between machines, allowing for adaptive responses to varying production demands. This adaptability not only streamlines workflows but also enables the creation of complex geometries that were previously difficult or impossible to achieve. As a result, businesses are able to meet consumer demands for personalized products while maintaining cost-effectiveness and high-quality standards.

Exploring the Future of Milling Machining: Innovations Transforming the Manufacturing Landscape - Integrating Smart Automation in Milling Processes

| Technology | Description | Benefits | Implementation Cost | Impact on Efficiency |

|---|---|---|---|---|

| IoT Integration | Connecting milling machines to the internet for real-time data exchange. | Enhanced monitoring and predictive maintenance. | $15,000 - $30,000 | Up to 20% increase in productivity. |

| Artificial Intelligence | Use of AI algorithms for optimizing cutting parameters. | Reduced material waste and improved part quality. | $20,000 - $50,000 | 30% improvement in quality consistency. |

| Robotics | Automated robotic arms for loading and unloading parts. | Minimized downtime and increased safety. | $25,000 - $70,000 | By 40% in cycle time reductions. |

| Cloud Computing | Centralized data storage and analytics for milling operations. | Improved data accessibility and decision-making. | $10,000 - $20,000 | Enhanced overall operational efficiency by 25%. |

Sustainability Practices in Modern Milling Operations

The milling industry is undergoing a significant transformation with a growing emphasis on sustainability practices. As reported by the Manufacturing Sustainability Report 2023, approximately 64% of manufacturing companies are implementing eco-friendly materials and processes, demonstrating a clear shift towards greener operations. In modern milling operations, companies are adopting advanced technologies such as green cutting fluids and energy-efficient machinery. This not only reduces carbon footprints but also enhances productivity by decreasing waste and energy consumption.

Moreover, the use of additive manufacturing techniques is being integrated with traditional milling processes, leading to precision and reduced resource consumption. According to the Global Manufacturing Innovation Study, over 50% of manufacturers plan to invest in sustainable practices over the next five years. With regulatory pressures and consumer demand for greener products, the milling sector is prioritizing sustainable practices, ensuring that their methodologies align with global environmental standards. This evolution not only benefits the planet but also positions companies favorably in an increasingly competitive market.

Future Trends: The Role of AI and Machine Learning in Milling

The integration of artificial intelligence (AI) and machine learning in milling machining is revolutionizing the manufacturing landscape. These technologies offer unprecedented capabilities for optimizing production processes and enhancing efficiency. AI systems analyze vast amounts of data to predict machine performance, identify maintenance needs, and fine-tune machining parameters to achieve better precision. This not only improves product quality but also reduces downtime and operational costs, making manufacturers more competitive in the global market.

Tips: To maximize the benefits of AI in milling, companies should invest in training their workforce to leverage these technologies effectively. Encouraging collaboration between engineers and data scientists can lead to innovative solutions tailored to specific machining challenges.

Additionally, as automation becomes increasingly vital in milling operations, businesses must stay attuned to emerging trends. The demand for smart machines that communicate with one another and adapt to varying production needs is on the rise. Implementing robust AI-driven systems can help manufacturers thrive amid evolving market conditions, ensuring that they remain at the forefront of the industry.

Related Posts

-

Future Trends in Best Milling Machining Market Analysis for 2025 Insights

-

Embracing the Future of Manufacturing How the Best Multi Axis CNC Milling Machines will Shape 2025 Technology Trends

-

Unlocking Quality: A Comprehensive Guide to Choosing the Best CNC Screw Machine Manufacturers

-

Ultimate Guide to Maximizing Efficiency with Axis CNC Machines in Your Workshop

-

Unlocking the Secrets to Sourcing Top Notch Cnc Cutting Suppliers Worldwide

-

Unmatched Manufacturing Excellence: Discover the Best Screw Machines from China’s Leading Factory

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219