What Are the Different Types of Ball Bearings?

Ball Bearings are essential components in many machines. They facilitate smooth rotational or linear movements. Understanding the different types of ball bearings can improve efficiency and performance.

There are numerous types of ball bearings, each designed for specific applications. For example, deep groove ball bearings are widely used in electric motors and appliances. On the other hand, angular contact ball bearings are better for high-speed applications. Each type offers unique benefits and potential drawbacks.

Choosing the right ball bearing is crucial for machine longevity. An improper selection may lead to increased wear and tear. It can cause unexpected downtime and maintenance costs. Overall, knowing the variations in ball bearings can enhance your projects and streamline operations.

Types of Ball Bearings and Their Applications

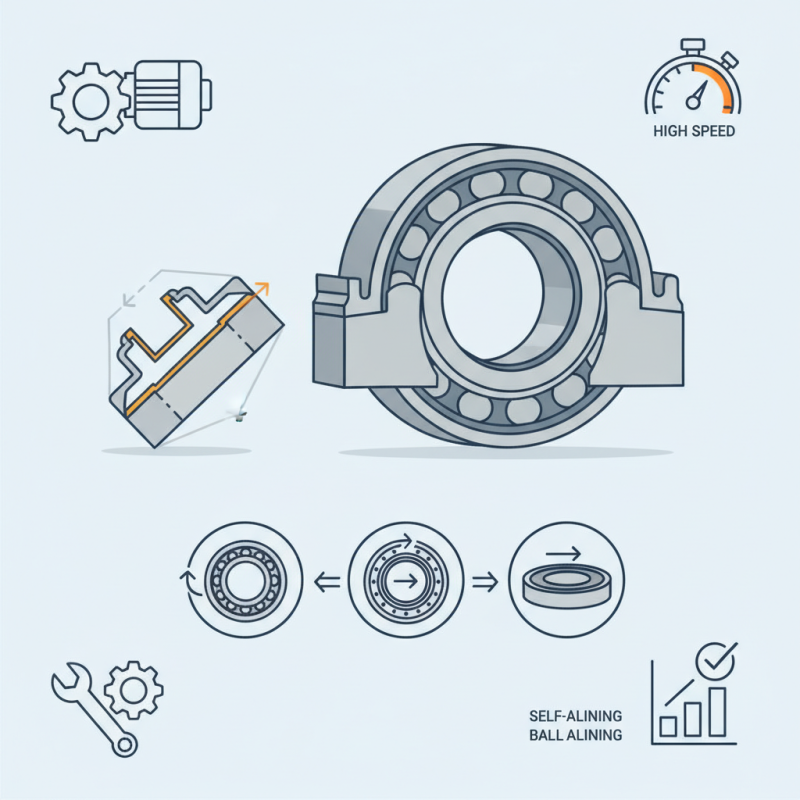

Ball bearings are essential components used in various machinery. Different types serve unique purposes based on their design and application. Standard types include deep groove, angular contact, and self-aligning ball bearings. Each type has specific advantages and limitations that influence their usage.

Deep groove ball bearings are versatile. They can handle radial and axial loads well. They are commonly found in electric motors and automotive applications. However, they may not perform well under extreme angles or misalignment. Angular contact ball bearings come with specific angles and excel in handling axial loads. They are often used in precision instruments but can be sensitive to misalignment.

Self-aligning ball bearings are unique. They can tolerate misalignment, making them suitable for vibrating machinery. Yet, their load capacity is generally lower than other types. Understanding these differences is crucial for proper selection. Analyzing application requirements ensures optimal performance. Mistakes in selection can lead to inefficiencies, increased wear, or even failure.

Types of Ball Bearings and Their Applications

Standard Ball Bearings: Construction and Features

Standard ball bearings are essential components in various mechanical systems. They consist of an outer ring, an inner ring, balls, and a cage. This simple design allows for smooth rotation and reduced friction, making them ideal for many applications. A report by the Bearing Industry Association notes that standard ball bearings account for about 60% of the global bearing market. Their versatility is evident in industries ranging from automotive to aerospace, where reliability is crucial.

The construction of standard ball bearings uses materials such as chrome steel, stainless steel, or ceramic. Chrome steel is common due to its durability and resistance to wear. However, it can be imperfect under extreme temperatures. The balls inside the bearing play a vital role in load distribution. Proper alignment is critical; misalignment can lead to premature failure. According to a recent study, nearly 30% of bearing failures are attributed to improper installation or lubrication. This reflects a need for careful quality control in manufacturing and assembly processes.

Angular Contact Ball Bearings: Design and Usage

Angular contact ball bearings are crucial in various applications. They are designed to support both radial and axial loads. This unique ability allows them to handle higher speeds and loads more effectively than standard bearings. According to a report by Research and Markets, the global ball bearings market is projected to reach $26.48 billion by 2025. Angular contact bearings play a significant role in this growth.

The design of angular contact ball bearings is quite distinctive. They have an inner and outer raceway that forms an angle relative to the bearing axis. This configuration provides the capacity to manage combined loads. The contact angle varies based on the specific application, typically ranging from 15 to 40 degrees. Data shows that bearings with a larger contact angle can support heavier axial loads. However, they may generate more friction, highlighting the balance required in their use.

Despite their advantages, there are challenges. Installing angular contact bearings can be tricky. Misalignment can lead to premature failure. Regular maintenance is essential to avoid excessive wear. A study published in the Journal of Mechanical Engineering found that improper installation can reduce bearing life by up to 50%. Therefore, attention to detail during installation can significantly impact their performance and longevity.

Self-Aligning Ball Bearings: Benefits and Limitations

Self-aligning ball bearings are designed to accommodate misalignment. They consist of two rows of balls and a spherical outer raceway. This unique design allows for self-correction, making them ideal for applications with shaft deflection. The benefits are clear. They reduce friction and wear, enhancing the overall lifespan of machinery.

However, they also come with limitations. They are not always suitable for heavy radial loads. Their capacity for axial loads is also lower compared to other types. In some cases, insufficient alignment can lead to premature failure. Users might face challenges in installation if not properly aligned.

These bearings require regular maintenance. Lubrication is essential to prevent overheating. Neglecting this can lead to inefficiencies. Understanding these aspects is vital for effective use. Balancing their benefits and drawbacks is key for optimal application.

Thrust Ball Bearings: Characteristics and Applications

Thrust ball bearings are designed to support axial loads while allowing rotation between the parts. They consist of a ball and a nearby raceway. This design makes them uniquely suited for applications where load direction is critical. Aircraft engines and industrial gearboxes often rely on their efficiency.

The construction of thrust ball bearings varies. They can be single or double-direction types. A single-direction thrust bearing handles load from one side. Meanwhile, a double-direction variant supports loads from both sides. Proper installation is crucial. Misalignment can lead to premature wear.

In service, these bearings face challenges. High temperatures may change their characteristics. Lubrication is vital, yet it can be tricky. Too much grease may cause overheating. Too little can lead to wear. Each application has unique requirements. Choosing the right type is not always straightforward.

Article Source:

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219