What is a Damper Actuator and How Does it Work?

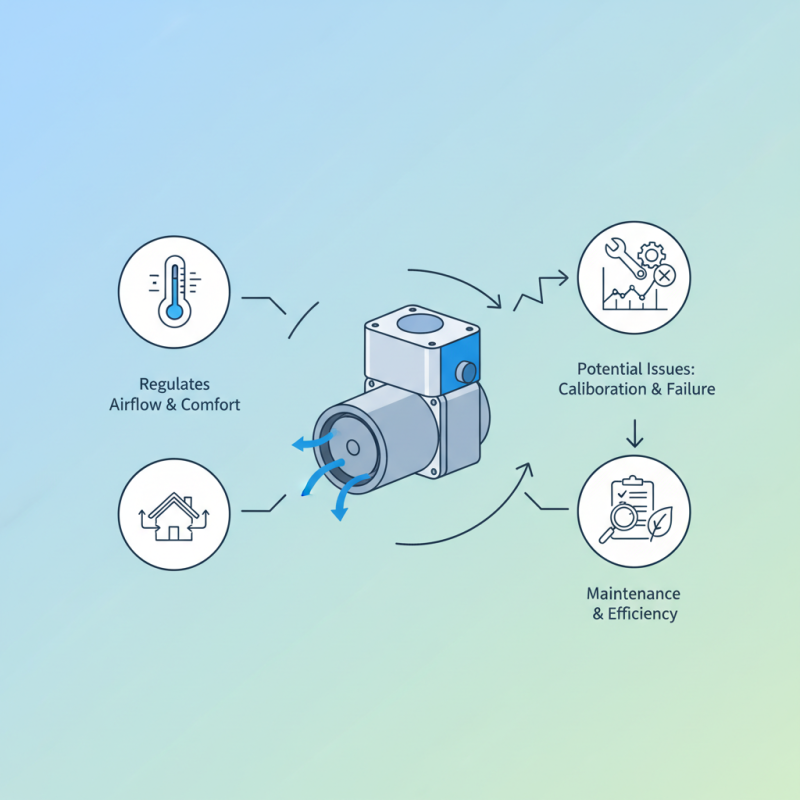

A Damper Actuator is a crucial component in many HVAC systems. It regulates airflow and ensures proper ventilation. These devices play a significant role in maintaining comfort within indoor spaces.

Understanding how a Damper Actuator works is essential for anyone involved in building management or HVAC systems. These actuators control damper blades, influencing air distribution. However, not all implementations are perfect.

Issues can arise, such as incorrect calibration or mechanical failures. These can lead to uneven airflow, creating discomfort. Therefore, regular maintenance and checks are vital to ensure optimal performance and efficiency. Adopting a proactive approach may lead to improved indoor air quality and energy savings.

What is a Damper Actuator?

A damper actuator is a crucial component in HVAC systems. It controls the airflow within ducts by adjusting dampers. These dampers can open or close to regulate air movement, enhancing comfort and efficiency. A well-functioning actuator maintains accurate airflow.

Typically, these actuators can be electric, pneumatic, or hydraulic. Electric actuators are common due to their efficiency and ease of use. They receive signals from a thermostat or control system. The signal prompts the actuator to adjust the damper position. Yet, sometimes, the signals can be inconsistent, causing airflow issues.

Understanding how a damper actuator works is essential. Regular maintenance can help avoid common pitfalls, like stuck dampers. Ignoring these issues can lead to discomfort and high energy bills. It's vital to monitor the actuator's performance regularly for optimal system function.

Damper Actuator Performance Overview

This bar chart illustrates the key performance metrics of a damper actuator, including response time, position accuracy, torque output, and power consumption. Understanding these specifications helps in evaluating the efficiency and effectiveness of damper actuators in various applications.

Types of Damper Actuators Available

When it comes to damper actuators, several types cater to different applications. Electric actuators are widely used for their efficiency. They convert electrical energy into mechanical motion, acting swiftly to open or close dampers. Often popular in building ventilation systems, they can operate with minimal noise. Reliable performance is a key factor here.

Pneumatic actuators use compressed air for movement. They are robust and can handle high forces. These actuators are common in industrial settings where quick response times are essential. However, they may need more maintenance due to air leaks. In contrast, hydraulic actuators deliver powerful operation with fluid power. They are often employed in heavy-duty applications. These actuators can be overkill for smaller systems, though.

Choosing the right actuator involves careful consideration. Each type has advantages and drawbacks. Some may find electric actuators lacking in power for larger dampers. Others may struggle with the complexity of pneumatic systems. It’s crucial to analyze the specific requirements before making a decision. An informed choice can improve efficiency and performance.

How Damper Actuators Function Mechanically

Damper actuators play a critical role in regulating airflow in HVAC systems. They control the opening and closing of dampers, which manage the flow of air through ducts. Mechanically, a damper actuator consists of several parts, including a motor, a linkage system, and the damper itself. The motor drives the mechanism, enabling precise adjustments to airflow.

When the actuator receives a signal from a thermostat, the motor engages. It turns a spindle that moves the damper blade. This blade can open partially or fully, impacting air volume. Mechanical components often experience wear over time. This wear might lead to improper damper positioning.

Adjusting the actuator can sometimes resolve airflow issues. However, it's essential to monitor the system regularly. When dampers do not function as intended, it can disrupt air distribution. Understanding how these components work together is crucial. Regular maintenance helps avoid future problems. Knowing these details isn’t always straightforward; sometimes, evaluation is needed.

Applications of Damper Actuators in HVAC Systems

Damper actuators play a crucial role in HVAC systems. They regulate airflow, improving indoor air quality. These devices can adjust the position of dampers automatically, ensuring optimal ventilation. In many buildings, they help maintain consistent temperatures, contributing to energy efficiency. This functionality is particularly important in areas with varying climate conditions.

In commercial applications, damper actuators are often used for controlling air distribution in large spaces. They can respond to changes in temperature or occupancy, adjusting airflow accordingly. However, installation and calibration can be tricky. Sometimes, actuators may not align perfectly with dampers, causing inefficiencies. Regular maintenance checks can help identify these issues early.

Residential HVAC systems also benefit significantly from damper actuators. They allow for personalized airflow in different rooms. Homeowners can create comfort zones tailored to their preferences. Occasionally, however, users may neglect to adjust settings seasonally, leading to wasted energy. It's essential to ensure that these devices function properly to maximize efficiency and comfort.

Maintenance and Troubleshooting for Damper Actuators

Damper actuators play a vital role in HVAC systems. Proper maintenance is crucial. Statistics indicate that 40% of HVAC failures relate to actuator issues. Regular inspections help prevent these failures. Look for signs like unusual noises or inconsistent airflow.

Troubleshooting damper actuators can be straightforward. Start by checking the electrical connections. A loose wire can cause erratic performance. Ensure that the actuator's linkages are free of obstructions. Blockages can lead to incorrect positioning, affecting efficiency. According to recent industry reports, a 10% increase in actuator responsiveness can significantly improve system performance.

Sometimes, the issue is not mechanical. Controls may need recalibration. Look at the control signals. Incorrect settings can prevent the actuator from smartly responding. Documenting any changes and testing functionality regularly can help identify ongoing issues. Be proactive. Ignoring minor problems often leads to larger, costlier repairs later.

Article Source:

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219