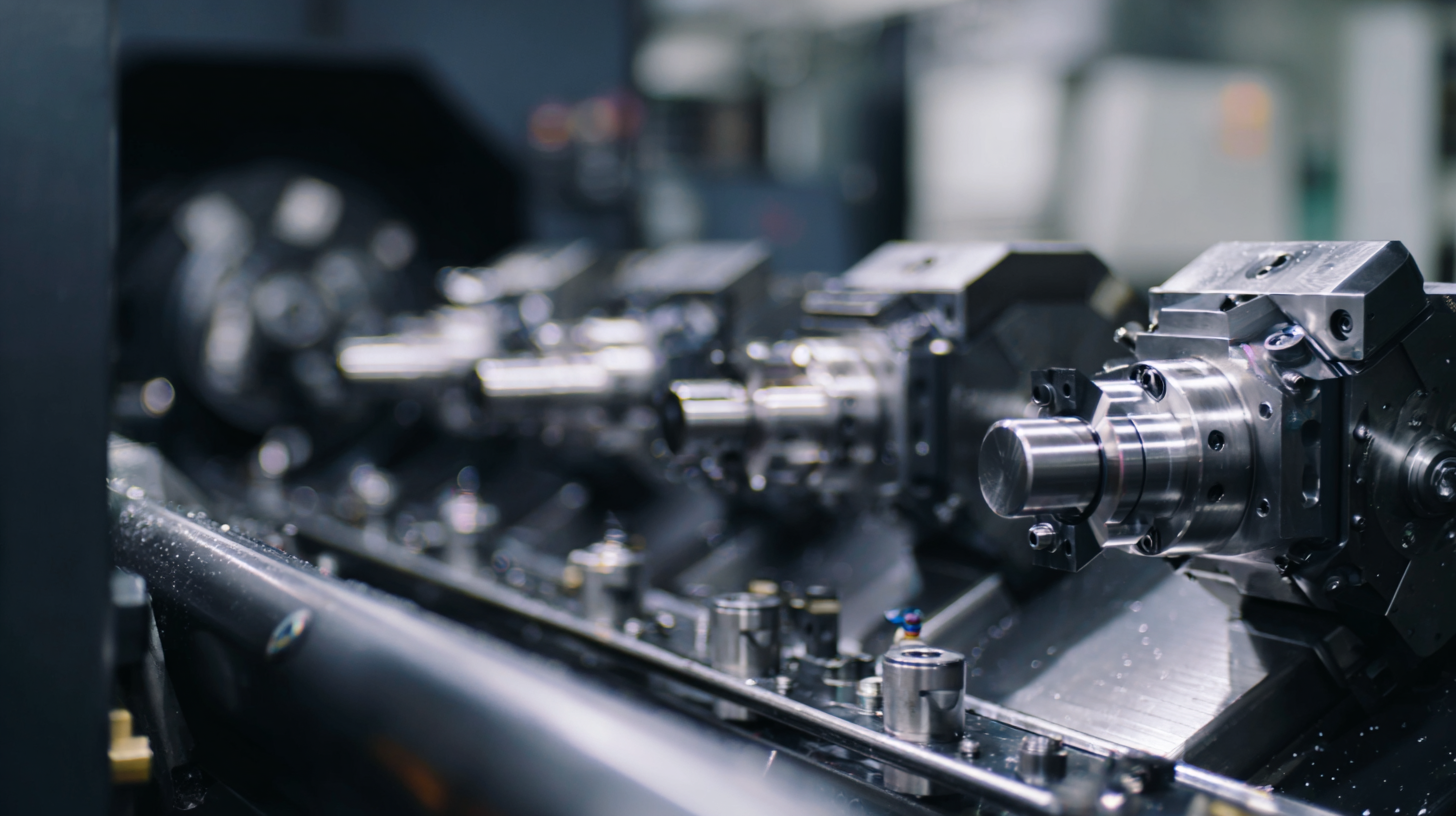

Choosing the Right Manufacturer for Best Cnc Parts and Tailored Solutions for Your Needs

In the rapidly evolving landscape of manufacturing, choosing the right manufacturer for CNC parts is critical for businesses seeking tailored solutions to meet their specific needs. According to a recent report by the International Federation of Robotics, the market for CNC machining is expected to reach $100 billion by 2025, driven by advancements in automation and precision engineering.

As industries increasingly demand custom components with higher accuracy and efficiency, selecting a manufacturer who can provide high-quality CNC parts becomes paramount. This blog will explore key considerations in choosing a manufacturer, highlighting industry trends and providing a comprehensive checklist to ensure that you make informed decisions that align with your operational requirements and future growth.

Identifying Your Specific CNC Parts Needs for Tailored Solutions

Identifying specific CNC parts needs is crucial for businesses looking to optimize their manufacturing processes. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117.93 billion by 2025, growing at a CAGR of 6.2%. This burgeoning demand emphasizes the importance of selecting a manufacturer that not only understands the market trends but can also provide tailored solutions to meet unique requirements.

One of the primary steps in identifying your CNC parts needs is understanding the materials and processes involved in your projects. For instance, a study by Grand View Research indicates that demand for precision components in the automotive and aerospace sectors is driving innovation in CNC manufacturing. Knowing whether you require high tolerance parts, specialized materials, or unique designs can significantly impact your choice of manufacturer. By articulating these needs, companies can ensure they partner with manufacturers equipped to deliver customized solutions that enhance efficiency and productivity.

Furthermore, evaluating potential manufacturers based on their ability to adapt to specific industry standards and regulatory requirements is essential. For instance, the medical device sector requires stringent compliance with ISO 13485 standards. Choosing a manufacturer that specializes in your sector can lead to a more seamless integration of CNC parts into your production line, saving both time and resources.

Evaluating Manufacturer Capabilities: Quality, Reliability, and Experience

When selecting a manufacturer for CNC parts, evaluating their capabilities is paramount. A comprehensive analysis should focus on three key areas: quality, reliability, and experience. According to a report by Grand View Research, the global CNC machine market is anticipated to reach $100.3 billion by 2025, emphasizing the industry's push towards enhanced manufacturing standards. Manufacturers with ISO certification demonstrate a commitment to maintaining high quality through stringent quality control processes.

**Tip:** Always request samples and specifications to assess the quality of a manufacturer's work before making any commitments.

Reliability is equally crucial; a manufacturer’s ability to consistently deliver parts on time can significantly impact your production timelines. A 2020 survey by Deloitte found that 79% of companies prioritize supplier reliability over cost. This underlines the need to partner with a manufacturer that has a proven track record of timely delivery and communication.

**Tip:** Investigate potential manufacturers’ client testimonials and case studies to gauge their reliability and performance under pressure.

Experience is another vital factor, as manufacturers with years in the industry are more likely to navigate challenges effectively. According to a report by Markets and Markets, experienced manufacturers invest significantly in the latest technologies and innovations, resulting in better tailored solutions for various industries.

**Tip:** Look for manufacturers that have experience in your specific industry to ensure they understand your unique requirements and can provide optimal solutions.

Choosing the Right Manufacturer for Best CNC Parts and Tailored Solutions for Your Needs

| Manufacturer Capability | Criteria | Rating (1-5) | Comments |

|---|---|---|---|

| Quality Assurance | Certifications (ISO, etc.) | 5 | High industry standards. |

| Reliability | Delivery Timelines | 4 | Usually on time, minor delays possible. |

| Experience | Years in Business | 5 | Established in the market for over 20 years. |

| Technical Expertise | Skilled Workforce | 5 | Highly trained and experienced technical team. |

| Customer Support | After-Sales Service | 4 | Responsive support but could improve. |

Understanding Material Options for CNC Parts Customization

When it comes to custom CNC parts, selecting the right material is crucial for achieving your desired performance and durability. Various materials such as aluminum, stainless steel, and plastics offer distinct advantages depending on the intended application. For instance, aluminum is often favored for its lightweight nature and excellent machinability, making it ideal for aerospace components. Conversely, stainless steel provides superior strength and corrosion resistance, making it a popular choice for medical and industrial applications.

Additionally, the specific requirements of your project can greatly influence your material choice. If you need parts that can withstand high temperatures, consider materials like titanium or advanced polymers that can maintain structural integrity under stress. Customization options also include surface treatments and coatings that enhance mechanical properties or aesthetic appeal.

By understanding the material options available for CNC parts, you can make informed choices that ensure your end products meet both functional and design requirements.

The Importance of Communication and Collaboration with Manufacturers

Effective communication and collaboration are pivotal when selecting a manufacturer for CNC parts. Engaging in open dialogue with potential manufacturers from the outset can provide invaluable insights into their capabilities, production processes, and quality control measures. Articulating your specific needs and expectations not only helps in aligning both parties’ goals but also fosters a productive partnership. When manufacturers fully understand your project requirements, they are more likely to deliver tailored solutions that meet your specifications.

Moreover, establishing a collaborative working relationship encourages transparency and trust, which are essential for successful manufacturing outcomes. Regular updates and feedback loops can help in addressing any issues promptly, ensuring that production stays on track. This ongoing engagement allows for adjustments and refinements, ultimately leading to higher quality CNC parts. Furthermore, a manufacturer who values collaboration will often welcome suggestions and be more responsive to changes, resulting in a smoother workflow and enhanced overall satisfaction with the final product.

Assessing Post-Production Support and Services for CNC Parts

When choosing a manufacturer for CNC parts, the importance of post-production support and services cannot be overstated. According to a report by MarketsandMarkets, the CNC machine market is expected to reach $100.9 billion by 2025, reflecting a growing need for efficient production methods. A substantial part of this efficiency comes from the level of post-production support that a manufacturer offers. Services such as quality assurance, inventory management, and turnaround time are crucial factors that can influence your production cycles and overall costs.

Moreover, research from Deloitte indicates that manufacturers who prioritize after-sales service can improve customer satisfaction rates by up to 30%. This statistic highlights the necessity of assessing potentially overlooked aspects, such as technical support and maintenance services, when selecting a manufacturer. These support services not only enhance the functionality of the CNC parts but also ensure that any issues are promptly addressed, thus preventing costly downtimes. As the demand for custom solutions escalates, manufacturers that invest in comprehensive post-production services will stand out as the best partners for your CNC projects.

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219