How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

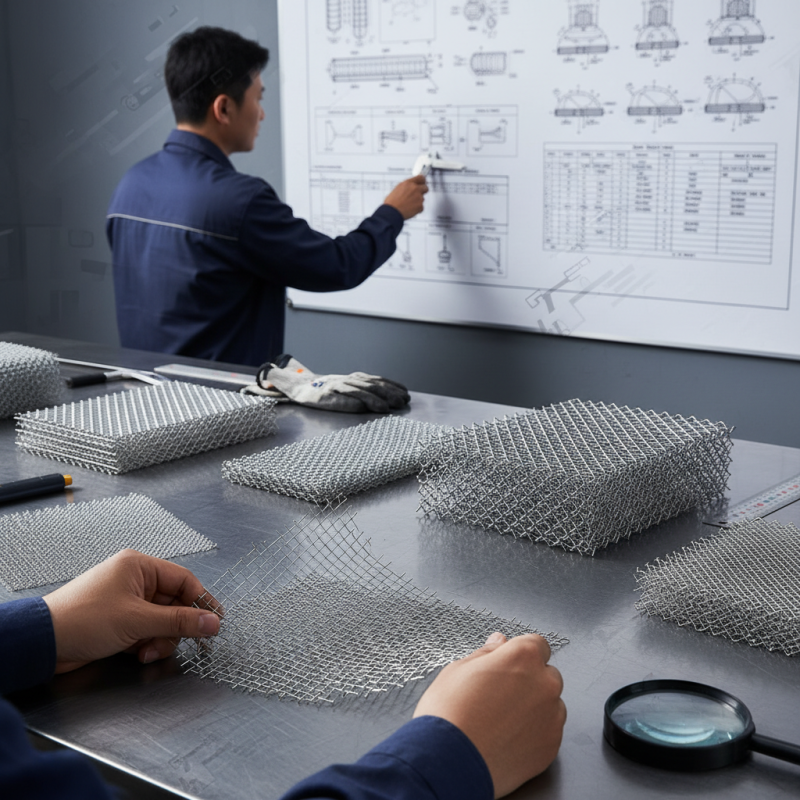

When it comes to selecting the right stainless steel wire mesh, expert insights can be invaluable. John Smith, a leading figure in the wire mesh industry, states, "Understanding your specific needs is crucial for making the best choice." The versatility of stainless steel wire mesh makes it essential in various applications, from filtration to architectural design.

Choosing the wrong mesh can lead to inefficiencies. Thickness, wire diameter, and weave type all play vital roles. A precise selection ensures durability and functionality. Some users may overlook these details, which can lead to costly mistakes. For example, using a fine mesh where a coarse one is required can hinder performance.

In a marketplace filled with options, it is easy to feel overwhelmed. Taking time to reflect on your specific requirements can yield better results. Whether it's for industrial use or creative projects, matching your needs to the appropriate stainless steel wire mesh is key. These choices are not as straightforward as they may seem.

Understanding the Different Types of Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, understanding the different types available is crucial. There are various varieties, each suited for specific applications. For instance, woven wire mesh is commonly used in filtration and fencing. Welded wire mesh, on the other hand, offers increased strength and durability. According to industry reports, the global demand for stainless steel wire mesh is projected to grow at a CAGR of 5.2% from 2023 to 2030.

Different grades of stainless steel also affect the properties of the wire mesh. Types 304 and 316 are the most prevalent, with Type 316 demonstrating superior corrosion resistance. This makes it ideal for marine and chemical applications. Interestingly, not all projects require the highest-grade materials. Assessing the environment and purpose of use can lead to cost savings.

Be mindful of potential pitfalls. Overspecified wire mesh can lead to unnecessary expenses. Underestimating the conditions can result in early degradation. Striking a balance is key for performance and budget. Choose wisely and reflect on your choices for better outcomes.

Key Factors to Consider When Choosing Stainless Steel Wire Mesh

When choosing stainless steel wire mesh, consider the mesh type. Different types serve unique purposes. For example, welded wire mesh offers strength, while woven mesh provides flexibility. The choice depends on your specific application.

Another critical factor is the wire diameter. Thicker wires offer more durability but may reduce flexibility. Conversely, thinner wires allow for easier handling but can wear out faster. Think about where and how you will use the mesh.

Consider the mesh opening size as well. Smaller openings filter finer particles but might limit airflow. Larger openings, on the other hand, allow better ventilation but may not trap smaller debris effectively. Balancing these factors can be tricky, and your needs might change over time. Evaluate your priorities regularly to ensure you have the right mesh for your current demands.

Applications of Stainless Steel Wire Mesh in Various Industries

Stainless steel wire mesh is widely used across various industries. Its durability and resistance to corrosion make it a preferred choice in many applications. For example, in the food industry, it is utilized for sieving and filtering. A report from Grand View Research indicates that the demand for wire mesh in food processing is expected to grow by 5% annually.

In the construction sector, stainless steel mesh provides structural support. It's often used in concrete reinforcement, which helps improve stability. The global construction market is projected to witness significant growth, further increasing the demand for durable materials like stainless steel wire mesh. That reflects an evolving market trend.

**Tips:** When choosing wire mesh, consider the mesh opening size. Smaller openings offer finer filtration. Always check the mesh gauge for strength. Consider the environment too. Harsh conditions might require thicker gauge meshes to ensure longevity.

Industries also use stainless steel wire mesh for safety and security. For instance, it is used in guardrails and partitions. While these applications are effective, improper installation can lead to risks. Regular maintenance checks are essential to ensure safety standards.

Applications of Stainless Steel Wire Mesh in Various Industries

Evaluating Wire Diameter and Opening Size for Your Needs

When choosing stainless steel wire mesh, wire diameter and opening size are crucial factors. The wire diameter influences strength and durability. Thicker wires can handle heavy loads. They also resist deformation, but they may not provide the flexibility needed for certain applications. On the other hand, thinner wires offer more convenience in handling and installation. However, they could be less sturdy when dealing with significant stress.

Opening size determines the mesh's functionality. A smaller opening can filter finer particles, while larger openings allow for better airflow. It's essential to match the opening size with your specific requirements. For instance, in filtration applications, finer openings are usually necessary. But in environments requiring strength, larger openings may be preferable, even if they compromise certain filtering capabilities.

Reflect on your unique needs before selecting wire mesh. Consider factors like environmental exposure, intended use, and budget constraints. It’s easy to overlook the balance between strength and flexibility. Sometimes, the chosen mesh may not meet initial expectations, prompting reevaluation. Assessing both wire diameter and opening size can significantly affect the overall performance of your wire mesh solution.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

| Wire Diameter (mm) | Opening Size (mm) | Mesh Count (per inch) | Applications |

|---|---|---|---|

| 0.5 | 1.0 | 24 | Filtration, Food Processing |

| 1.0 | 2.0 | 18 | Industrial Applications, HVAC |

| 1.5 | 3.0 | 12 | Architectural Features, Decorative Applications |

| 2.0 | 4.0 | 10 | Security Fencing, Grill Applications |

| 3.0 | 5.0 | 8 | Construction, Heavy Duty Applications |

Maintenance Tips for Long-lasting Stainless Steel Wire Mesh

Stainless steel wire mesh is durable, but it requires proper care. Regular cleaning prevents grime buildup. Use warm water and mild soap to wash the mesh. A soft brush can help scrub stubborn stains. Rinse thoroughly to avoid soap residue. This routine keeps the mesh looking new.

Inspect the wire mesh regularly for any signs of corrosion or damage. Pay attention to areas with heavy usage. If you spot rust, act quickly. Remove the rust using a fine-grade sandpaper or wire brush. Reapply protective coatings as needed.

Avoid using harsh chemicals. They can damage the stainless steel surface. Instead, focus on gentle cleaning products. Proper storage is also key. Keep the mesh in a dry area to prevent moisture. These habits lead to longer-lasting stainless steel wire mesh. Regular upkeep may seem tedious, but it pays off in durability.

Article Source:

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219